- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

Top 10 Yuken Valve Solutions for Optimal Hydraulic Performance

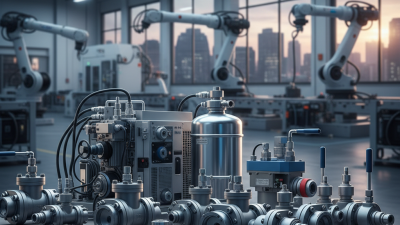

In the world of hydraulic systems, achieving optimal performance is paramount for efficiency and productivity. As David Turner, a renowned expert in hydraulic technology, aptly stated, “The right valve can make all the difference in enhancing system reliability and performance.” Among the plethora of options available, Yuken valves stand out as a prominent solution, combining innovative design with robust functionality.

Yuken valves are engineered to provide precise control over fluid flow and pressure in hydraulic applications, which is crucial for industries ranging from manufacturing to construction. Their versatility and reliability make them a preferred choice for engineers and technicians seeking to maximize the performance of hydraulic systems. This article explores the top 10 Yuken valve solutions, focusing on their unique features and benefits that contribute to optimal hydraulic performance. By examining these solutions, professionals will gain insights into how Yuken valves can elevate their hydraulic systems to new heights, ensuring both efficiency and durability in demanding operational environments.

Table of Contents

[Hide]

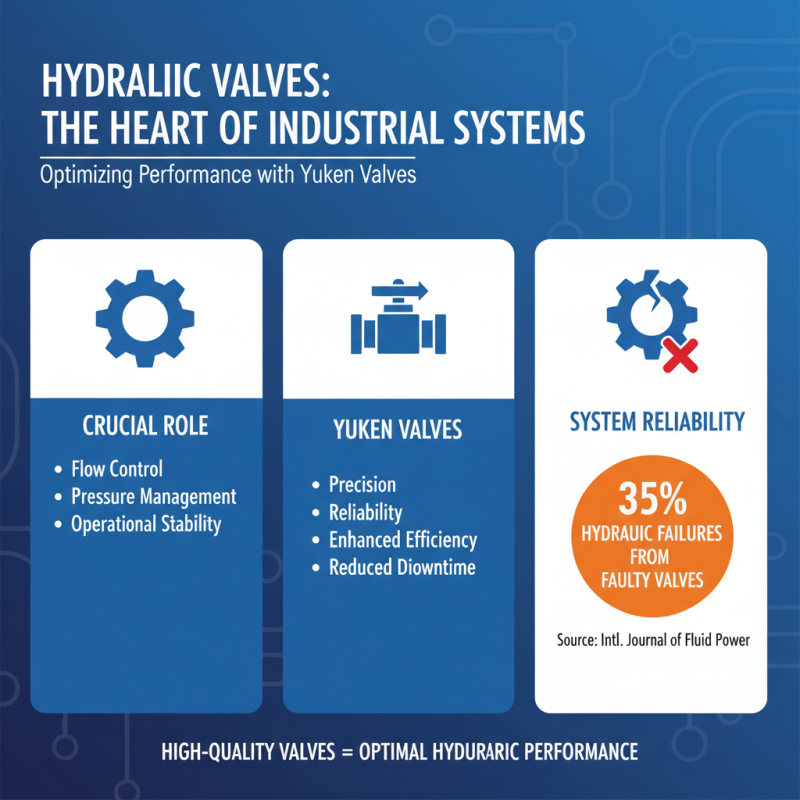

Yuken Valve Overview: Importance in Hydraulic Systems

Hydraulic systems play a crucial role in various industrial applications, and the efficiency of these systems largely depends on the performance of the valves used. Yuken valves, recognized for their precision and reliability, are integral components in optimizing hydraulic operations. Their design facilitates better flow control and pressure management, which are essential for maintaining operational stability in hydraulic applications. According to a report by the International Journal of Fluid Power, nearly 35% of hydraulic system failures can be traced back to faulty valve performance, highlighting the importance of selecting high-quality valves.

To ensure optimal hydraulic performance, it is vital to understand the different configurations and functionalities of Yuken valves. These valves are engineered to provide enhanced flow rate control, reduced energy consumption, and improved responsiveness. Industry studies indicate that the integration of advanced valves can lead to a 20% increase in energy efficiency within hydraulic systems. Maintaining proper valve selection and installation practices is essential for achieving these benefits.

**Tip:** Regular maintenance and inspection of hydraulic valves are crucial for prolonged system reliability. Implementing a routine check-up schedule can help identify potential issues before they escalate, ensuring continuous and efficient operation. Investing in high-quality hydraulic components can yield significant long-term savings by reducing downtime and maintenance costs.

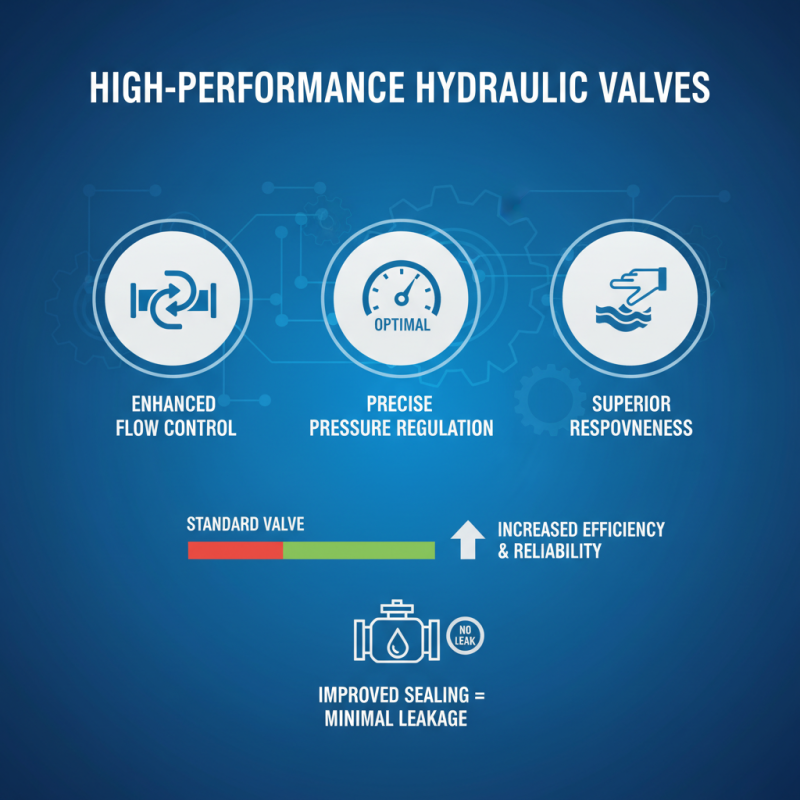

Key Features of Yuken Valves for Enhanced Performance

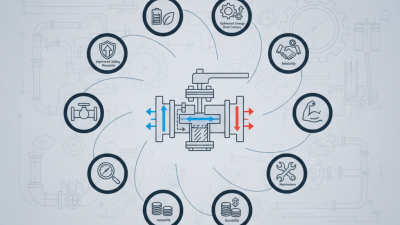

When it comes to hydraulic performance, the choice of valve can significantly impact the efficiency and reliability of any system. Key features of high-performance valves often include enhanced flow control, precise pressure regulation, and superior responsiveness to varying operational demands. Valves designed with improved sealing technologies minimize leakage and ensure optimal flow rates, thereby increasing the overall efficiency of hydraulic systems.

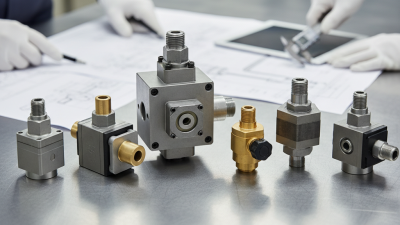

Another essential aspect is the construction material and design of these valves. Utilizing high-strength materials not only extends the lifespan of the valve but also enhances its performance under high-pressure conditions. Moreover, features like integrated filters can help maintain fluid cleanliness, protecting the system from contamination and wear.

**Tips:** When selecting a valve, it's crucial to consider the specific requirements of your hydraulic application, such as pressure ratings and intended fluid types. Additionally, regular maintenance and testing can help in identifying potential wear and ensuring that the valves perform optimally throughout their service life. Always consult technical specifications to ensure compatibility with existing systems, which can prevent costly downtime and enhance overall performance.

Top Yuken Valve Models and Their Applications

In the hydraulic industry, selecting the right valve is crucial for achieving optimal performance and efficiency. Yuken valve solutions are widely recognized for their reliability and versatility across various applications, including industrial machinery, mobile equipment, and energy systems. According to industry reports, the global hydraulic valve market is projected to reach USD 32.1 billion by 2025, indicating a growing demand for innovative hydraulic solutions that optimize performance and reduce operational costs.

Among the top models available in the Yuken range, the pressure control valves stand out for their ability to maintain system stability under varying load conditions. These valves play a vital role in preventing system overloads while enhancing energy savings. Similarly, directional control valves are designed to manage fluid flow direction effectively, providing precise control in complex hydraulic circuits. Reports indicate that the utilization of advanced directional control valves can lead to an efficiency increase of up to 15% in hydraulic systems, which significantly contributes to overall productivity and reduced maintenance costs.

In applications such as construction machinery and manufacturing processes, Yuken's proportional control valves offer enhanced responsiveness and adaptability. Their ability to modulate flow and pressure according to real-time demands ensures that hydraulic systems operate at peak performance. With the continued evolution of hydraulic technologies, staying informed about valve functionalities and their applications is essential for organizations aiming to leverage hydraulic efficiency in their operations.

Innovative Technologies in Yuken Valve Design

Innovative technologies in valve design play a crucial role in enhancing hydraulic performance. Modern advancements focus on improving the efficiency and responsiveness of hydraulic systems, which are critical in industries ranging from aerospace to manufacturing. By integrating smart sensors and digital control systems, contemporary valve designs can provide real-time data and analytics, allowing for precise adjustments and improved system monitoring. This level of intelligence not only optimizes performance but also extends the lifespan of hydraulic components by preventing overloading and ensuring they operate within safe parameters.

In addition to sensor integration, the use of advanced materials and manufacturing techniques has significantly transformed valve design. Lightweight materials improve ease of installation and reduce the overall weight of hydraulic systems, contributing to energy efficiency. Also, innovations such as 3D printing allow for the production of complex geometries that traditional manufacturing methods cannot achieve. These designs enhance fluid flow characteristics and minimize resistance, leading to better performance and lower energy consumption. By focusing on such innovative technologies, the evolution of valve systems continues to address the demanding requirements of modern industrial applications.

Top 10 Yuken Valve Solutions for Optimal Hydraulic Performance - Innovative Technologies in Yuken Valve Design

| Solution Name | Technology Type | Application | Efficiency Rating | Key Feature |

|---|---|---|---|---|

| High-Flow Valve | Hydraulic | Industrial Machinery | 95% | Compact Design |

| Proportional Valve | Electro-Hydraulic | Robotics | 90% | Precise Control |

| Directional Control Valve | Hydraulic | Construction Equipment | 92% | Versatile Operations |

| Pressure Relief Valve | Safety Device | Hydraulic Systems | 98% | Safety Assurance |

| Flow Control Valve | Hydraulic | Agricultural Equipment | 93% | Adjustable Flow |

| Hydraulic Cylinder Control | Integrated System | Manufacturing Automation | 97% | High Responsiveness |

| Servo Valve | Digital Control | Aerospace | 94% | High Precision |

| Load Sensing Valve | Hydraulic | Construction | 96% | Energy Efficiency |

| Multi-Function Valve | Hydraulic | Mobile Equipment | 91% | Space Saving |

| Flow Dividers | Hydraulic | Industrial Machines | 89% | Distributive Flow |

Best Practices for Maintenance and Optimization of Yuken Valves

Maintaining optimal hydraulic performance in hydraulic systems requires a deep understanding of valve components and their upkeep. Regular maintenance of valves can significantly increase the reliability and efficiency of hydraulic operations. According to a report from the International Fluid Power Society, nearly 70% of hydraulic system failures are attributed to improper maintenance of critical components, such as valves. To mitigate these risks, it is crucial to adhere to a schedule of routine inspections, cleaning, and necessary replacements, which can extend the lifespan of hydraulic systems by up to 30%.

Best practices for optimizing the performance of hydraulic valves include ensuring proper installation to minimize stress on the components, as well as employing correct fluid selection based on operating conditions. Reports indicate that improper fluid can lead to increased wear and tear, negatively impacting valve performance. Moreover, regular monitoring of operating parameters—such as temperature, pressure, and flow rates—can help identify potential issues before they lead to downtime. Implementing an effective maintenance strategy not only improves performance but can also result in operational cost savings of 20% or more by reducing unscheduled maintenance events and extending equipment lifespans.

Best practices for optimizing the performance of hydraulic valves include ensuring proper installation to minimize stress on the components, as well as employing correct fluid selection based on operating conditions. Reports indicate that improper fluid can lead to increased wear and tear, negatively impacting valve performance. Moreover, regular monitoring of operating parameters—such as temperature, pressure, and flow rates—can help identify potential issues before they lead to downtime. Implementing an effective maintenance strategy not only improves performance but can also result in operational cost savings of 20% or more by reducing unscheduled maintenance events and extending equipment lifespans.

Related Posts

-

Understanding Yuken Directional Valves and Their Applications in Modern Hydraulic Systems

-

2025 How to Choose the Best Yuken Valve for Your Hydraulic System

-

Why Choose Yuken Valves for Your Industrial Applications

-

Exploring the Benefits of Yuken Directional Valves for Enhanced Hydraulic Performance

-

Top 10 Benefits of Pilot Operated Check Valves in Industrial Applications

-

7 Essential Tips for Choosing the Right Hydraulic Valve for Your Application