- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

Top Trends in 2025 for Check Valves You Need to Know About

As industries continue to evolve, the importance of check valves in ensuring efficient fluid control cannot be overstated. According to renowned industry expert Dr. Emily Johnson, "Check valves are the unsung heroes of hydraulic systems, providing critical safety and reliability." In the forthcoming years leading up to 2025, understanding the latest trends in check valves will be essential for engineers and operators alike. This comprehensive examination will delve into emerging technologies, novel materials, and sustainability practices that are poised to redefine the check valves landscape.

With safety regulations tightening and environmental concerns gaining prominence, it is imperative for professionals in the field to stay informed about advancements that can enhance operational efficiency and reduce environmental impact. The focus on automation and smart technology integration will significantly influence the design and functionality of check valves moving forward. As we explore these trends, we will also highlight influential innovations that promise to optimize performance and uphold safety standards, paving the way for a more reliable future in fluid management systems.

Table of Contents

[Hide]

Emerging Technologies in Check Valve Design for 2025

As we look towards 2025, the design of check valves is evolving rapidly, driven by the integration of emerging technologies. One significant trend is the incorporation of advanced materials that enhance durability and performance, allowing check valves to withstand more extreme conditions while reducing maintenance requirements. These materials, such as high-performance plastics and composites, not only improve corrosion resistance but also contribute to lightweight designs that can positively impact overall system efficiency.

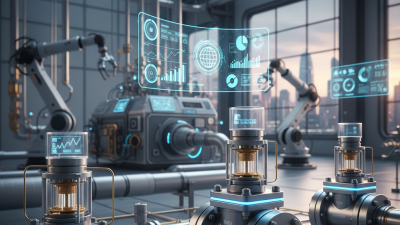

Another exciting development is the use of smart technology in check valves. The integration of sensors and IoT capabilities enables real-time monitoring of valve performance, providing operators with valuable data on flow rates, pressure fluctuations, and potential malfunctions. This predictive maintenance approach not only enhances operational reliability but also helps in minimizing downtime, as issues can be identified and addressed proactively. As digital transformation reshapes industrial processes, check valves equipped with these technologies are set to play a pivotal role in creating more efficient and resilient systems in various applications.

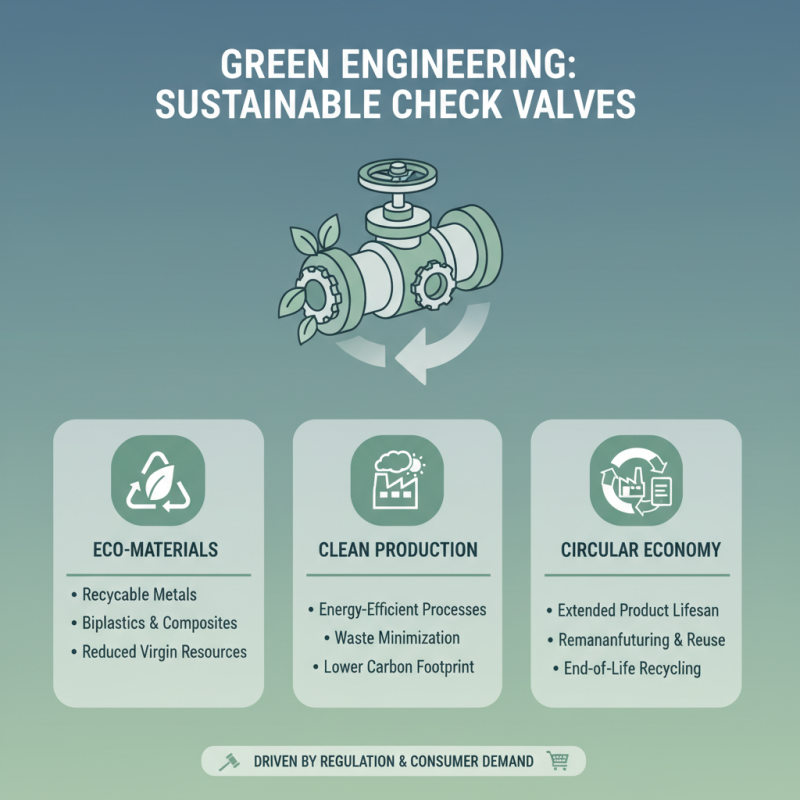

Sustainability Trends Impacting Check Valve Production

Sustainability has become a pivotal focus in the manufacturing of check valves, reflecting the broader trends in industrial production. As environmental concerns rise, manufacturers are adopting eco-friendly practices throughout the lifecycle of check valves, from material selection to production processes. This includes utilizing recyclable materials and incorporating energy-efficient manufacturing techniques that minimize waste and reduce the carbon footprint. The trend is driven not only by regulatory pressures but also by increasing consumer demand for sustainable products, prompting companies to innovate in their approaches.

Furthermore, advancements in technology are facilitating sustainable practices within the industry. For instance, the implementation of digital tools and automation allows for greater precision in production, reducing material waste and enhancing efficiency. The shift towards circular economy principles encourages manufacturers to design check valves that can be easily refurbished or recycled at the end of their lifecycle. This proactive stance not only aligns with global sustainability goals but also enhances brand reputations, as companies demonstrate their commitment to responsible manufacturing practices and environmental stewardship. The integration of these sustainability trends into check valve production will be crucial in meeting future demands and fostering a greener industrial landscape.

Advancements in Materials for Enhanced Check Valve Performance

The evolution of check valves is largely influenced by advancements in materials that enhance their performance. As industries demand higher efficiency and reliability, the selection of materials plays a crucial role in the design and durability of check valves. In 2025, we can expect increased utilization of advanced composites and alloys that offer superior corrosion resistance and temperature tolerance. These materials not only enhance the longevity of check valves but also improve their ability to function in extreme environments, making them suitable for a wider range of applications.

When choosing materials for check valves, it’s essential to consider the specific operational conditions. For example, environments with high temperatures or corrosive substances require specialized materials to prevent premature failure. Additionally, incorporating lightweight materials can significantly reduce the overall weight of the valve without compromising its structural integrity.

Tips for selecting the right check valve material include assessing the chemical compatibility with fluids being handled, evaluating thermal properties to ensure performance under varying temperatures, and considering the mechanical strength to withstand pressure fluctuations. Prioritizing these factors can lead to more efficient systems and minimize maintenance costs in the long run.

Market Demand Shifts: Industries Driving Check Valve Innovation

The check valve market is experiencing significant shifts in demand driven by various industries, fundamentally reshaping the landscape of valve innovation. One of the most impactful sectors is the renewable energy industry, which is rapidly adopting advanced check valves to improve system efficiency and reliability. As solar and wind energy technologies advance, the need for high-performing, durable check valves that can withstand fluctuating pressures and varying environmental conditions is crucial. This trend is pushing manufacturers to innovate with materials and designs that enhance performance, ultimately contributing to more sustainable energy solutions.

Moreover, the oil and gas industry continues to be a significant driver of check valve innovation, particularly in response to the increasing focus on safety and environmental protection. Enhanced safety regulations and the need for robust systems in extraction, transportation, and refining processes have led to the development of smarter check valves equipped with sensors for real-time monitoring. These innovations not only improve operational efficiency but also reduce the risk associated with leaks and failures, thus addressing both corporate responsibility and regulatory compliance. As industries evolve and new challenges arise, the trend towards smart, reliable check valves will likely shape the future of the market, highlighting the necessity for ongoing innovation.

Regulatory Changes and Their Influence on Check Valve Standards

As industries continue to evolve, regulatory changes are playing a pivotal role in shaping the standards for check valves in 2025. Regulatory bodies are increasingly focused on enhancing safety and environmental sustainability, which directly influences the design and manufacturing processes of these crucial components. New regulations are set to enforce stricter performance standards, demanding that check valves not only meet existing guidelines but also incorporate advanced materials and technologies to improve efficiency and reliability.

Additionally, these regulatory changes encourage companies to adopt more transparent practices in their operations. This shift towards accountability means that manufacturers must provide comprehensive documentation of compliance with updated standards. As industries strive to align with these requirements, we can expect a shift towards greater innovation in check valve technologies, incorporating smart features such as IoT connectivity and automated monitoring systems. Overall, the influence of regulatory changes on check valve standards will create a landscape characterized by enhanced performance, safety, and environmental responsibility in the coming years.

Top Trends in 2025 for Check Valves

This chart displays the projected growth in demand and changes in regulatory focus for check valves across different industries by 2025. The data reflects anticipated trends as organizations adapt to new standards and regulations.

Related Posts

-

2025 Top 10 Check Valves Trends Innovations and Market Statistics

-

Understanding the Role of Check Valves in Modern Industrial Systems

-

Maximizing Efficiency: How Directional Control Valves Transform Hydraulic Systems

-

Exploring the Benefits of Advanced Hydraulic Directional Valves for Efficient Fluid Control

-

How to Choose the Right Directional Control Valve for Your Project

-

Exploring the Benefits of Yuken Directional Valves for Enhanced Hydraulic Performance