- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

Understanding the Role of Check Valves in Modern Industrial Systems

In the realm of modern industrial systems, the significance of check valves cannot be overstated. These essential components play a pivotal role in preventing backflow and ensuring the efficient operation of fluid transport systems. According to a report by ResearchAndMarkets, the global check valves market is projected to reach USD 4.2 billion by 2026, growing at a compound annual growth rate (CAGR) of 6.1% from 2021. This growth reflects the increasing demand for automation and safety measures in various sectors, including oil and gas, water treatment, and power generation. Check valves serve as a safeguard against potential damage and inefficiencies in these systems, contributing to overall operational reliability and safety. Understanding the intricacies of check valves and their applications is therefore essential for engineers and operators striving to optimize performance in today's fast-evolving industrial landscape.

In the realm of modern industrial systems, the significance of check valves cannot be overstated. These essential components play a pivotal role in preventing backflow and ensuring the efficient operation of fluid transport systems. According to a report by ResearchAndMarkets, the global check valves market is projected to reach USD 4.2 billion by 2026, growing at a compound annual growth rate (CAGR) of 6.1% from 2021. This growth reflects the increasing demand for automation and safety measures in various sectors, including oil and gas, water treatment, and power generation. Check valves serve as a safeguard against potential damage and inefficiencies in these systems, contributing to overall operational reliability and safety. Understanding the intricacies of check valves and their applications is therefore essential for engineers and operators striving to optimize performance in today's fast-evolving industrial landscape.

Table of Contents

[Hide]

The Functionality of Check Valves in Fluid Control Systems

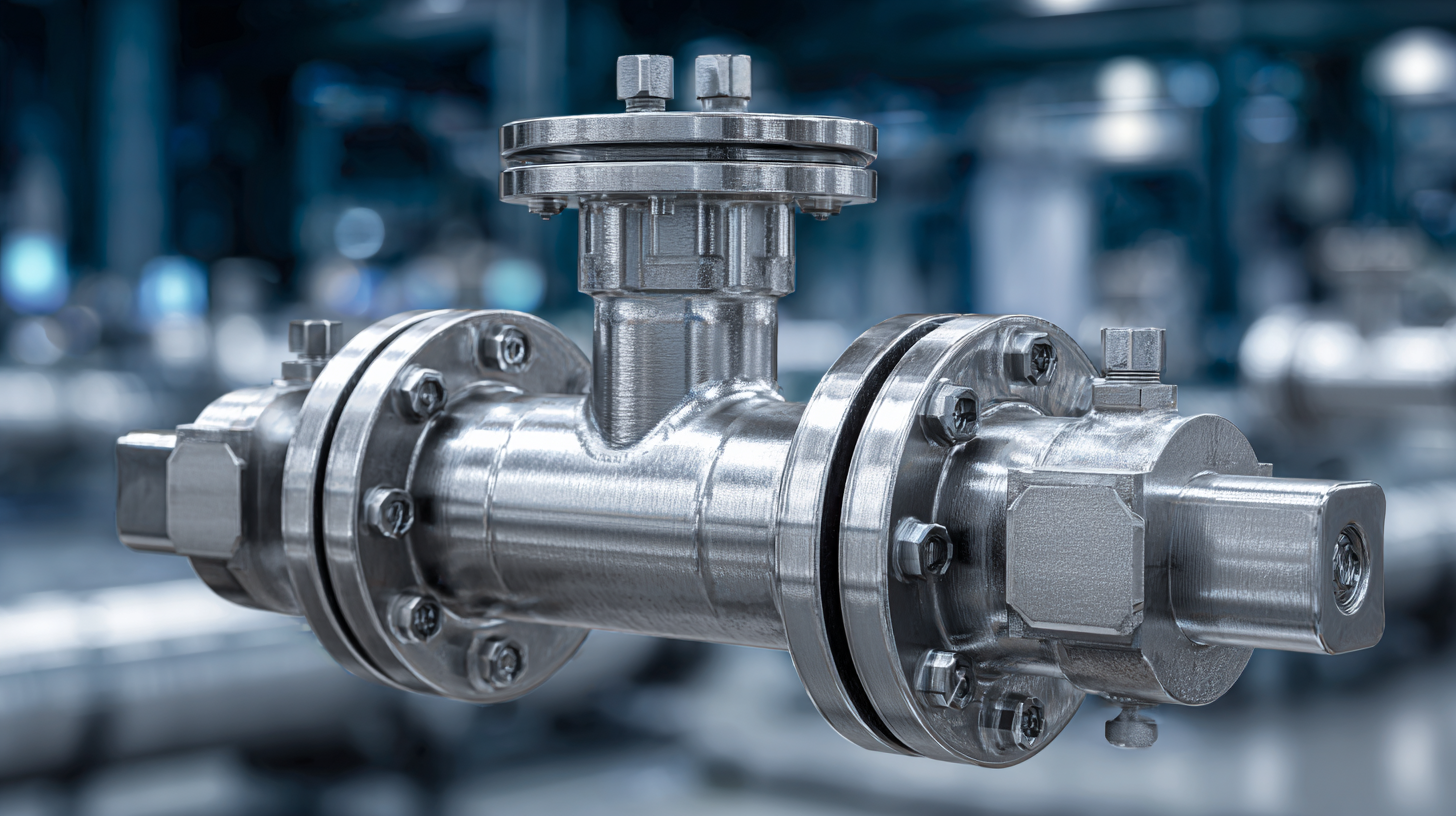

Check valves play a crucial role in fluid control systems by ensuring unidirectional flow and preventing backflow. This functionality is essential in various industrial applications, where maintaining the integrity of the fluid system is paramount. When fluid moves in the desired direction, the check valve opens, allowing smooth passage. However, if there’s a pressure drop or a reversal in flow, the valve automatically closes, restricting the return of the fluid. This mechanism protects equipment from potential damage and maintains operational efficiency in pipelines, pumps, and other critical components of fluid systems.

Check valves play a crucial role in fluid control systems by ensuring unidirectional flow and preventing backflow. This functionality is essential in various industrial applications, where maintaining the integrity of the fluid system is paramount. When fluid moves in the desired direction, the check valve opens, allowing smooth passage. However, if there’s a pressure drop or a reversal in flow, the valve automatically closes, restricting the return of the fluid. This mechanism protects equipment from potential damage and maintains operational efficiency in pipelines, pumps, and other critical components of fluid systems.

Furthermore, check valves contribute to system reliability by reducing the likelihood of contamination. In many industrial processes, the integrity of fluids must be preserved to ensure product quality and safety. By preventing backflow, check valves minimize the risk of mixing incompatible substances, which could lead to contamination and operational issues. Their design and materials cater to various pressures and temperatures, making them adaptable to a wide range of industrial environments. Consequently, check valves are an indispensable part of modern fluid control systems, ensuring smooth operation and longevity of industrial machinery.

Types of Check Valves and Their Applications in Industry

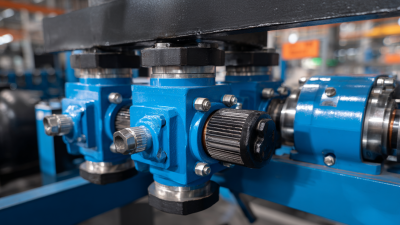

Check valves are essential components in modern industrial systems, serving to prevent backflow in various fluid applications. There are several types of check valves, each tailored for specific uses across different industries. The most common types include swing check valves, lift check valves, and ball check valves. Swing check valves operate with a hinged disc that swings open with flowing fluid and closes when flow reverses. This type is ideal for larger pipelines, especially in water treatment and drainage systems.

Lift check valves, on the other hand, feature a movable disc that rises to allow fluid to pass and drops back into place to prevent backflow. These valves are often used in high-pressure applications, and they can be found in oil refineries and chemical processing plants. Lastly, ball check valves utilize a ball that moves within a spherical casing to block reverse flow. This design allows for quick sealing and is commonly used in varying industrial applications, from pumping systems to irrigation. Each type of check valve has unique characteristics, making them crucial for maintaining system efficiency and safety in industrial settings.

Key Benefits of Implementing Check Valves in Industrial Processes

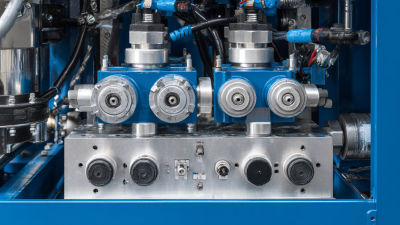

Check valves are essential components in modern industrial systems, providing critical benefits that enhance operational efficiency. One of the primary advantages of implementing check valves is their ability to prevent backflow in piping systems. This function is crucial in maintaining the correct flow direction and ensuring that fluids do not reverse, which could lead to equipment damage and process inefficiencies. By safeguarding against backflow, check valves help protect pumps, compressors, and other equipment from potential failures and costly repairs.

Another significant benefit of check valves is their role in maintaining system pressure. These valves allow for the smooth flow of liquids and gases while preventing unwanted reverse flow, which can cause fluctuations in pressure that might disrupt industrial processes. By stabilizing pressure levels, check valves contribute to consistent operational performance, reduce wear and tear on machinery, and ultimately enhance the reliability of production systems. In addition, the simplicity and low maintenance requirements of check valves make them a cost-effective solution for industries looking to optimize their processes and improve safety standards.

Understanding the Role of Check Valves in Modern Industrial Systems

| Dimension | Description | Key Benefits |

|---|---|---|

| Flow Direction Control | Ensure fluid flows in a single direction, preventing backflow. | Protects equipment from damage caused by reverse flow. |

| Pressure Maintenance | Helps maintain pressure in a system during off cycles. | Enhances efficiency and system reliability. |

| Reduced Risk of Contamination | Prevents the backflow of contaminants into clean systems. | Improves product quality and safety. |

| Ease of Maintenance | Simplified installation and replacement processes. | Reduces downtime and maintenance costs. |

| Versatility | Applicable in various industries and different fluid types. | Increases system adaptability to changing needs. |

Common Challenges and Solutions in Check Valve Operation

Check valves are essential components in modern industrial systems, enabling fluid flow in one direction while preventing backflow. However, their operation can present several challenges. One common issue is wear and tear due to the repetitive opening and closing action, which can lead to valve failure or leakage. This is particularly prevalent in high-pressure applications where the mechanical stress on the valve is significant. Regular maintenance and the use of durable materials can mitigate these issues, extending the lifespan of the valve.

Another challenge involves the potential for flow turbulence, especially in systems experiencing rapid flow changes. This turbulence can cause vibrations, which may result in damage to the valve and surrounding infrastructure. To address this, engineers often incorporate flow stabilizers or design the piping layout to minimize abrupt changes in direction. By carefully considering these factors during the design phase, industrial systems can improve the reliability and efficiency of check valve operation, ensuring smooth fluid management in various applications.

Understanding Check Valves Performance in Various Industrial Applications

This chart illustrates the frequency of common challenges faced by check valves across different industrial applications. The data indicates that the Chemical Processing sector encounters the most challenges, while the Manufacturing sector confronts the least. Addressing these challenges is crucial for enhancing reliability and efficiency in industrial systems.

Future Trends in Check Valve Technology for Industrial Use

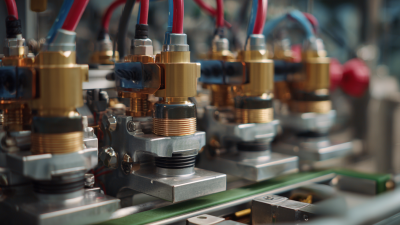

As industrial systems evolve, so does the technology surrounding check valves, which play a crucial role in ensuring efficient fluid flow and preventing backflow. Current trends highlight the industry's shift towards more advanced materials and automated solutions. According to a recent market analysis by Global Industry Analysts, the check valve market is projected to reach $5.2 billion by 2027, driven by an increasing need for reliability in critical applications like water management and oil and gas.

One significant trend is the integration of smart technology within check valves. These valves are being equipped with sensors that monitor parameters such as pressure and flow rates in real-time, enabling predictive maintenance. This innovation minimizes downtime and maximizes efficiency, a necessity in today’s competitive industrial landscape.

Tip: When selecting a check valve for your system, consider the materials compatible with your specific fluids and operational conditions to extend the valve's lifespan and maintain efficiency.

Additionally, the drive towards sustainability is pushing manufacturers to develop eco-friendly and energy-efficient valve solutions. Materials like biodegradable plastics and advanced composites are being explored, reducing the environmental impact while enhancing performance. Adapting to these trends not only meets regulatory demands but also positions companies favorably in a market increasingly focused on sustainable practices.

Tip: Stay informed about technological advancements in check valves to ensure your equipment meets future regulatory standards and performance expectations.

Related Posts

-

Unlocking Efficiency: The Vital Role of Hydraulic Pressure Relief Valves in Industrial Systems

-

Understanding the Importance of Hydraulic Pressure Control Valves in Modern Industrial Applications

-

Exploring the Benefits of Advanced Hydraulic Directional Valves for Efficient Fluid Control

-

The Essential Guide to Understanding Hydraulic Power Packs in Industrial Applications

-

The Future of Automation: How Servo Valves are Revolutionizing Industry Efficiency

-

Exploring the Benefits of Yuken Directional Valves for Enhanced Hydraulic Performance