- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

What is a Pilot Operated Check Valve and How Does It Work in Hydraulic Systems

In the intricate world of hydraulic systems, the significance of a pilot operated check valve cannot be overstated. According to renowned hydraulic expert Dr. John Smith, "The pilot operated check valve is essential for maintaining system pressure and ensuring flow control in complex hydraulic circuits." This statement highlights the critical role that these valves play in enhancing efficiency and safety within hydraulic operations.

In the intricate world of hydraulic systems, the significance of a pilot operated check valve cannot be overstated. According to renowned hydraulic expert Dr. John Smith, "The pilot operated check valve is essential for maintaining system pressure and ensuring flow control in complex hydraulic circuits." This statement highlights the critical role that these valves play in enhancing efficiency and safety within hydraulic operations.

A pilot operated check valve is designed to allow fluid flow in one direction while blocking it in the opposite direction, thanks to its unique piloting mechanism. This not only prevents backflow but also facilitates controlled motion in various hydraulic applications, from construction equipment to manufacturing machinery. Understanding how this valve functions and its advantages can drastically improve system performance and reliability, making it an indispensable component in modern hydraulic systems.

As we delve into the top aspects of pilot operated check valves, we will uncover their operational principles, benefits, and the reasons they are favored in both industrial and mobile hydraulic applications. By doing so, we aim to provide a comprehensive overview that empowers engineers to make informed decisions when selecting components for their hydraulic systems.

Table of Contents

[Hide]

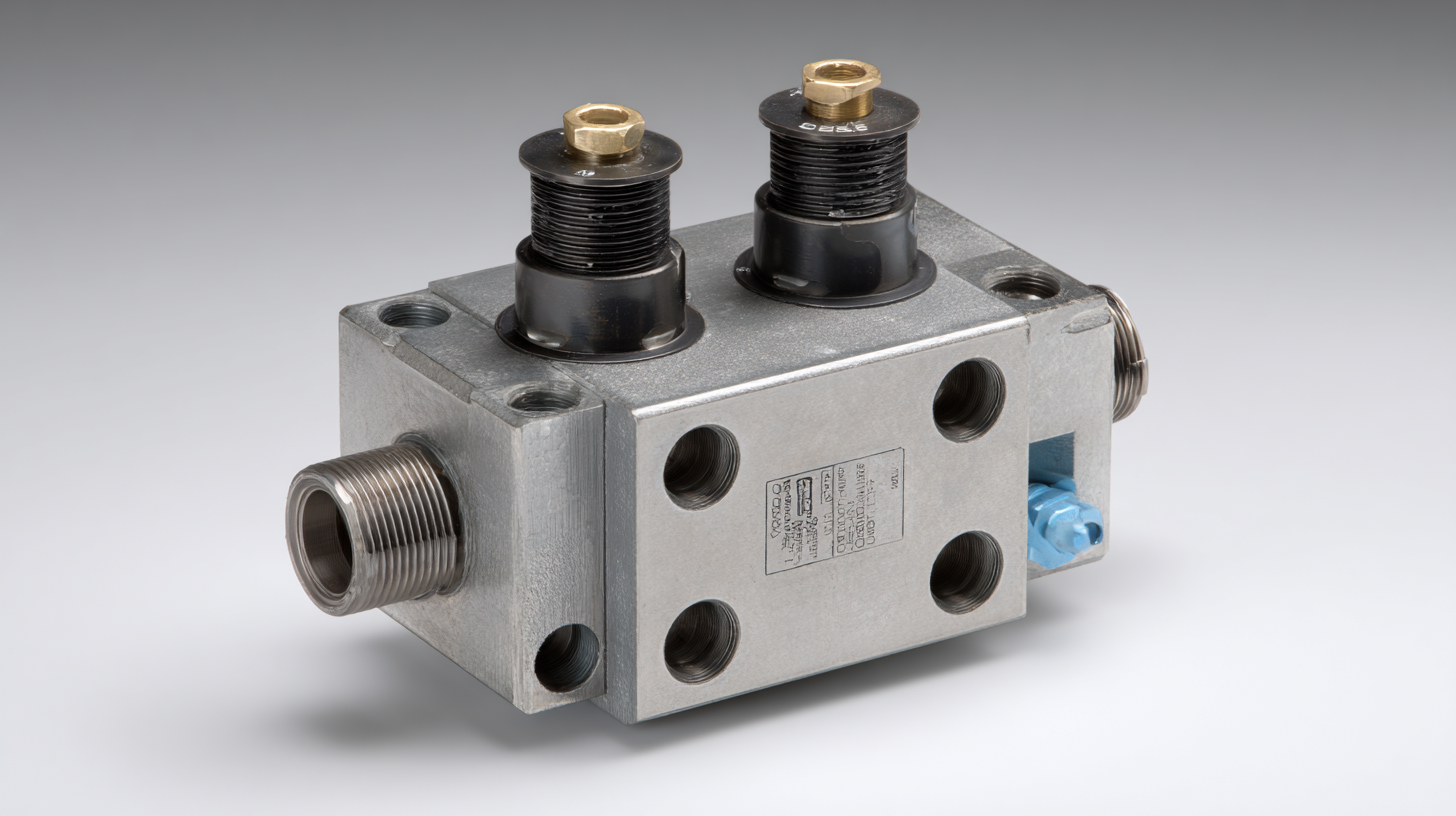

What Is a Pilot Operated Check Valve and Its Role in Hydraulic Systems

A pilot-operated check valve is a crucial component in hydraulic systems, designed to ensure the flow of fluid in one direction while preventing backflow. Its operation is facilitated by a pilot line that controls the valve opening, allowing for precise management of hydraulic pressure and flow. According to the International Fluid Power Society, nearly 70% of fluid power systems incorporate some form of check valve, underscoring the importance of these devices in enhancing system efficiency and reliability.

In hydraulic applications, the pilot-operated check valve functions by using system pressure to open the valve for forward flow, while a lower pressure on the pilot side causes the valve to close, effectively blocking any reverse flow. This feature is particularly beneficial in applications that require load-holding capabilities, providing stability and safety. Statistics from the Fluid Power Journal suggest that using pilot-operated check valves can reduce energy consumption by up to 15%, reflecting their pivotal role in optimizing operational performance in hydraulic circuits.

What is a Pilot Operated Check Valve and How Does It Work in Hydraulic Systems

| Dimension | Description |

|---|---|

| Function | Allows flow in one direction and blocks reverse flow. |

| Operation Type | Pilot operated, utilizing a small pilot pressure to control main flow. |

| Applications | Used in hydraulic circuits for load holding, system safety, and preventing backflow. |

| Advantages | Increased efficiency, reduced pressure drops, and enhanced control over fluid flow. |

| Key Components | Main valve, pilot valve, spring, and seals. |

| Common Issues | Wear and tear, leakage, or blockage leading to failure in function. |

| Maintenance Tips | Regular inspection, cleaning, and replacing worn components to ensure reliability. |

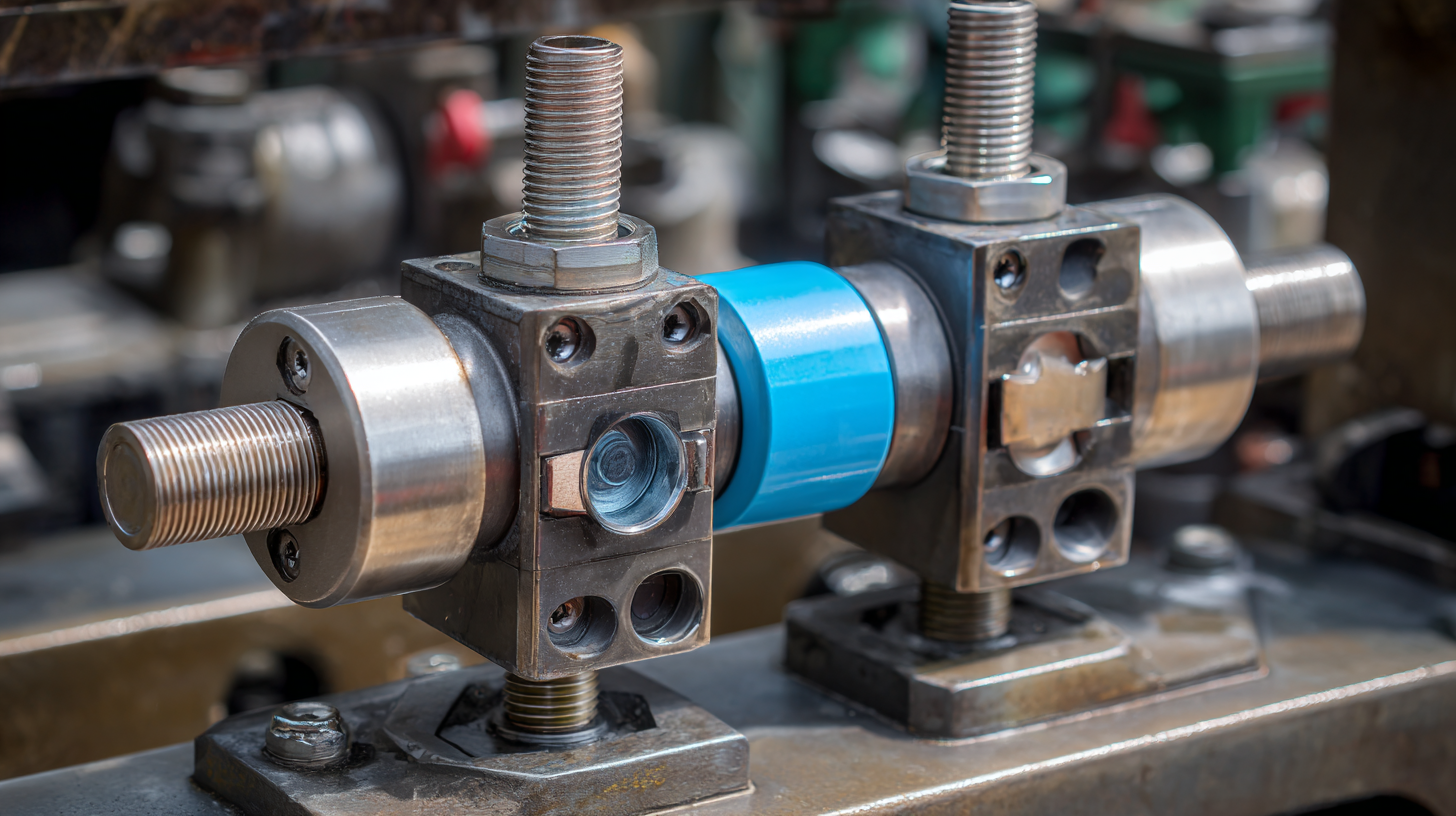

Understanding the Mechanics of Pilot Operated Check Valves

Pilot operated check valves are essential components in hydraulic systems, designed to allow fluid flow in one direction while preventing backflow. The mechanics behind these valves rely on a pilot pressure signal that determines their operation. When the system is under pressure, the pilot signal activates the valve, allowing fluid to flow through to the actuator. This enables components such as hydraulic cylinders to function smoothly, ensuring efficient operation within the hydraulic circuit.

Pilot operated check valves are essential components in hydraulic systems, designed to allow fluid flow in one direction while preventing backflow. The mechanics behind these valves rely on a pilot pressure signal that determines their operation. When the system is under pressure, the pilot signal activates the valve, allowing fluid to flow through to the actuator. This enables components such as hydraulic cylinders to function smoothly, ensuring efficient operation within the hydraulic circuit.

The unique design of pilot operated check valves involves a main valve and a pilot valve. The main valve remains closed until the pilot valve opens under sufficient pressure, which effectively overrides the main valve's closed position. This feature allows hydraulic systems to maintain pressure in the system while providing a safe and reliable means to control the flow. Additionally, these valves prevent unnecessary fluid loss and enable quick response times, which are vital in applications where precision and control are paramount.

Benefits of Using Pilot Operated Check Valves in Hydraulic Applications

Pilot Operated Check Valves (POCVs) offer significant advantages in hydraulic applications that enhance system efficiency and safety. One of the primary benefits is their ability to allow free flow in one direction while preventing backflow in the other, which is crucial for systems that require reliability. This feature reduces the risk of hydraulic shock and potential damage to components, ultimately prolonging the life of the hydraulic system.

Another substantial benefit is their high flow capacity, which enables quicker response times in hydraulic circuits. POCVs can accommodate larger flow rates without significant pressure drop, allowing for more responsive and dynamic operation in machinery during critical tasks. Additionally, their design often results in smaller, lighter assemblies compared to traditional check valves, contributing to overall space and weight savings in hydraulic systems. This compact nature facilitates easier integration into existing systems while maintaining performance efficiency.

Common Applications of Pilot Operated Check Valves in Industry

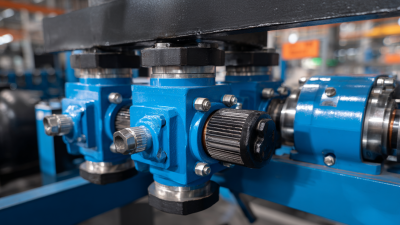

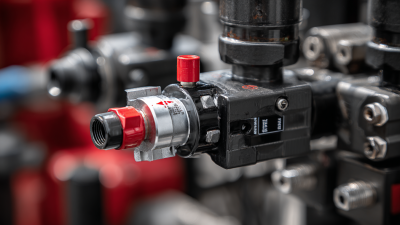

Pilot operated check valves play a crucial role in various industrial applications by ensuring unidirectional flow and providing system safety. These valves are commonly found in hydraulic systems where they prevent backflow, thus maintaining pressure and system integrity. One of the most common applications is in hydraulic mobile equipment, such as excavators and forklifts, where they help to control the movement of heavy loads effectively. By allowing fluid to flow in one direction while blocking reverse flow, they enhance operational efficiency and safety.

In manufacturing processes, pilot operated check valves are used in automated machinery where precise control of fluids is essential. For example, in assembly lines or robotic systems, these valves ensure that actuators receive the necessary pressure for smooth operation without the risk of pressure loss due to backflow. Additionally, they are utilized in agricultural equipment and process industries to maintain consistent fluid flow and pressure, significantly contributing to improved performance and reduced downtime in industrial operations.

Maintenance Tips for Ensuring Optimal Performance of Check Valves

Maintaining pilot operated check valves is essential for ensuring optimal performance in hydraulic systems. Regular inspections are crucial; operators should check for leaks, wear, and other signs of deterioration. Any fatigue on seals or internal components can lead to system malfunctions, impacting overall efficiency. Implementing a routine schedule for inspection helps in early detection of potential issues, allowing for timely replacements or repairs.

Additionally, proper fluid management plays a significant role in the longevity of check valves. Using the correct hydraulic fluid and maintaining its cleanliness prevents contaminants from entering the system, which can cause blockages or damage to valve components. Regularly changing the hydraulic fluid according to the manufacturer’s recommendations enhances valve performance and reduces the risk of failure. Furthermore, monitoring the operating temperature can also help identify underlying problems. Ensuring the system operates within recommended temperature ranges minimizes the risk of thermal degradation of the valve materials.

Pilot Operated Check Valve Performance Analysis

This bar chart showcases the performance metrics of pilot operated check valves in hydraulic systems, including flow rate, pressure drop, response time, and leakage rate. These metrics are crucial for maintaining optimal performance of hydraulic systems.

Related Posts

-

Understanding the Importance of Hydraulic Pressure Control Valves in Modern Industrial Applications

-

Understanding the Role of Hydraulic Valves in Modern Industrial Applications

-

Exploring Innovative Control Products: Transforming Industries with Smart Technology

-

Exploring the Benefits of Advanced Hydraulic Directional Valves for Efficient Fluid Control

-

Maximizing Efficiency: How Directional Control Valves Transform Hydraulic Systems

-

Understanding the Importance of Hydraulic Flow Control Valves in Modern Industrial Applications