- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

Why You Should Invest in a Hydraulic Unit for Efficient Machinery Operation

In today's fast-paced industrial landscape, the efficiency and reliability of machinery operations are paramount for maintaining a competitive edge. One of the most effective ways to enhance performance and maximize productivity is by investing in a hydraulic unit. Hydraulic units, which harness the power of fluid mechanics, offer superior force, speed, and precision compared to traditional mechanical systems. By utilizing these advanced systems, businesses can significantly reduce operational downtime while improving the overall effectiveness of their machinery.

The implementation of a hydraulic unit not only streamlines operations but also contributes to more robust maintenance practices. With their ability to provide consistent power output and ease of control, hydraulic units allow for smoother and more responsive machinery operation. This reliability translates into lower maintenance costs and less frequent equipment failures, ultimately safeguarding the bottom line. Furthermore, as industries evolve towards automation, incorporating hydraulic units becomes increasingly critical in adapting to modern technological demands.

Incorporating a hydraulic unit into your machinery setup represents a strategic investment that goes beyond mere cost savings. It paves the way for enhanced capabilities and innovation in operations. As businesses strive for greater efficiency and control in their processes, the advantages of hydraulic units become clear, positioning them as an indispensable component in the mechanical landscape of the future.

Table of Contents

[Hide]

Importance of Hydraulic Units in Machinery Operations

Hydraulic units play a crucial role in enhancing the performance and reliability of various machinery operations across multiple industries. According to a report by the International Fluid Power Society, hydraulic systems can deliver more power in a smaller size compared to traditional mechanical systems, allowing for more compact and efficient machinery designs. This is particularly beneficial in sectors such as construction, manufacturing, and transportation, where maximizing space and improving efficiency are paramount. In fact, industry experts estimate that hydraulic systems can improve energy efficiency by up to 30%, significantly reducing operational costs over time.

Moreover, hydraulic units are essential for providing precise control over machinery operations. The ability to adjust speed, force, and movement direction with exceptional accuracy allows operators to perform complex tasks that would be difficult or impossible with other power systems. The Fluid Power Industry report indicates that hydraulic technology can reduce cycle times by 10-20%, ultimately leading to increased productivity. As industries continue to adopt automation and advanced manufacturing techniques, the importance of hydraulic units in achieving operational excellence cannot be overstated. Integrating these systems into machinery not only ensures efficient performance but also enhances safety by improving load handling and reducing the risk of mechanical failure.

Key Benefits of Investing in Hydraulic Units

Investing in a hydraulic unit is essential for achieving efficient machinery operation in various industrial applications. One of the key benefits of hydraulic units is their ability to provide consistent and high levels of power with minimal energy consumption. This efficiency not only reduces operational costs, but also minimizes the environmental impact, making your machinery more sustainable. Additionally, hydraulic systems are highly versatile, allowing them to adapt to a wide range of operational needs, from manufacturing to construction.

Tips for maximizing the benefits of hydraulic units include regular maintenance and investing in quality components. Regular checks can prevent downtime and extend the lifespan of your equipment, ensuring that it operates at peak performance. Furthermore, selecting components that are compatible with your hydraulic system can enhance efficiency and reduce the likelihood of malfunctions.

Another significant advantage of hydraulic units is their compact design, which allows for space-saving arrangements. This is particularly beneficial in crowded work environments where optimizing space is crucial. When planning your layout, consider the positioning of your hydraulic units to ensure easy access for maintenance and operation, contributing to overall workflow efficiency.

How Hydraulic Units Enhance Operational Efficiency

Investing in a hydraulic unit can significantly enhance operational efficiency across various machinery applications. According to a report by the International Fluid Power Society, hydraulic systems can achieve efficiency levels up to 90%, mainly due to their ability to transmit power through incompressible fluids. This high efficiency translates to reduced energy consumption, lower operational costs, and extended machinery lifespan. With precise control over force and speed, hydraulic systems enable more efficient operations in industries ranging from manufacturing to construction, allowing for faster cycle times and improved productivity.

Tips for enhancing efficiency with hydraulic units include regular maintenance and monitoring of fluid levels. Keeping the hydraulic fluid clean and at optimal levels not only prolongs the life of the equipment but also ensures that the system operates within its best efficiency range. Furthermore, utilizing advanced hydraulic technologies, such as variable speed drives and electronic controls, can greatly optimize the performance of machinery, allowing for better energy management.

In addition to the direct benefits, integrating hydraulic units can improve workplace safety and reduce maintenance costs. Systems that operate efficiently with hydraulic power generate less heat and wear, minimizing the likelihood of mechanical failures. By adopting a proactive approach to hydraulic system management, businesses can enjoy improved operational efficiency and a more reliable machinery setup, ultimately leading to better overall performance in their operations.

Why You Should Invest in a Hydraulic Unit for Efficient Machinery Operation

Investing in hydraulic units can significantly enhance machinery operational efficiency, as illustrated by the increase in efficiency from 65% to 90% after implementing hydraulic technology. This data underscores the advantages of hydraulic systems in optimizing machinery performance.

Selecting the Right Hydraulic Unit for Your Machinery

When selecting the right hydraulic unit for your machinery, it is crucial to consider the specific requirements of your operations to enhance efficiency and productivity. According to a report from the International Fluid Power Society, properly chosen hydraulic systems can improve operational efficiency by over 15%, reducing energy consumption and downtime.

Key factors to contemplate include the unit's flow rate, pressure capability, and compatibility with your machinery. The flow rate, typically measured in liters per minute (LPM), must align with the machinery's operational needs to ensure optimal performance. Additionally, pressure ratings are essential; selecting a unit that can handle the required maximum pressure without risking failure is vital for safety and longevity. Research indicates that misjudging these parameters can lead to equipment failures, which result in costly repairs and prolonged operational halts.

Moreover, integrating advanced hydraulic units with features such as variable speed drives can provide further efficiency benefits. A study published in the Journal of Hydraulic Engineering noted that employing variable speed technology can lead to energy savings of up to 30% in certain applications. By carefully evaluating these aspects and investing in a suitable hydraulic unit, you not only foster a more efficient machinery operation but also contribute to long-term sustainability in your processes.

Maintenance Practices for Hydraulic Units to Ensure Longevity

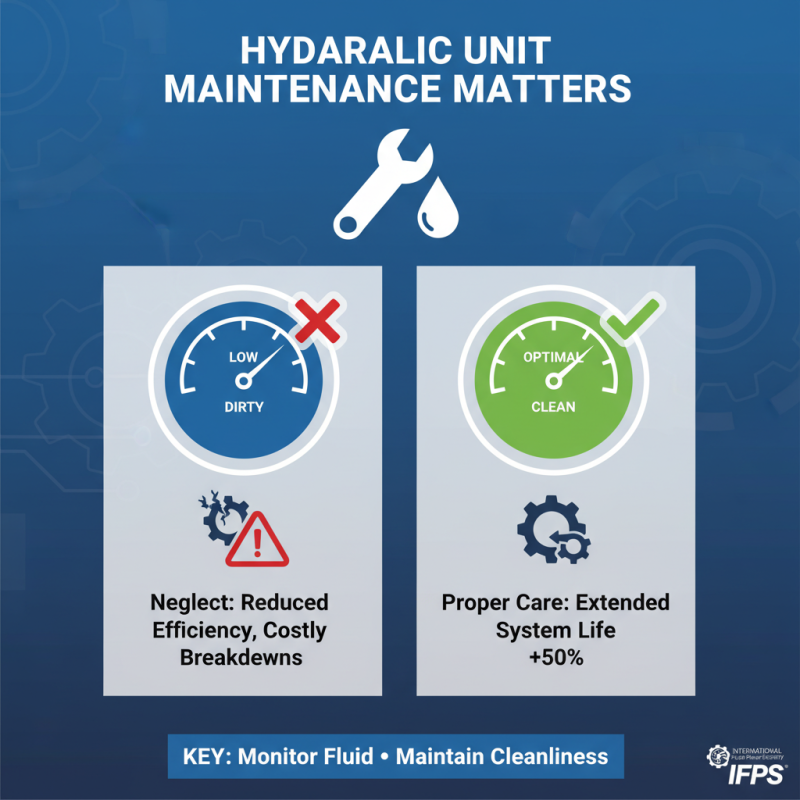

Hydraulic units play a critical role in the operation of various machinery and equipment, offering enhanced efficiency and power control. However, their performance and longevity heavily depend on consistent and proper maintenance practices. Regularly monitoring fluid levels and quality is essential, as contaminated hydraulic fluids can significantly reduce system efficiency and lead to costly breakdowns. According to a report by the International Fluid Power Society, maintaining the cleanliness of hydraulic fluid can extend system life by up to 50%.

Routine inspections are also vital in ensuring the integrity of hydraulic units. This includes checking for leaks, assessing seals and hoses for wear, and ensuring proper alignment of components. The Fluid Power Journal highlights that proactive maintenance can reduce unexpected downtime by up to 30%, thereby maximizing operational efficiency. Additionally, keeping detailed maintenance records allows for better tracking of performance issues and can help predict when a unit may require more extensive servicing or replacement. By prioritizing these maintenance practices, operators can ensure not only the longevity of their hydraulic units but also the consistent performance of their machinery.

Related Posts

-

The Essential Guide to Understanding Hydraulic Power Packs in Industrial Applications

-

Understanding the Importance of Hydraulic Flow Control Valves in Modern Industrial Applications

-

How to Choose the Right Hydraulic Unit for Your Industrial Needs

-

Top Hydraulic Unit Trends to Watch in 2025 for Optimal Performance

-

Exploring the Benefits of Advanced Hydraulic Directional Valves for Efficient Fluid Control

-

The Essential Guide to Understanding Pressure Relief Valves: Safety and Function Explained