- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

Understanding the Importance of Hydraulic Pressure Control Valves in Modern Industrial Applications

In today's rapidly evolving industrial landscape, the role of hydraulic pressure control valves has become increasingly critical to operational efficiency and safety. According to a report from Grand View Research, the global hydraulic valves market is projected to reach USD 28.1 billion by 2025, driven largely by the rising demand for advanced hydraulic systems in various sectors including manufacturing, construction, and automotive. Hydraulic pressure control valves, specifically, play a pivotal role in regulating fluid flow and maintaining system stability, thereby enhancing overall productivity. These valves not only ensure proper pressure management but also contribute to energy conservation, which is essential in a world focused on sustainability.

As industries continue to embrace automation and precision engineering, understanding the functionality and significance of hydraulic pressure control valves becomes paramount for engineers and decision-makers alike, paving the way for innovations that can drive performance and reliability in modern industrial applications.

Table of Contents

[Hide]

How Hydraulic Pressure Control Valves Function in Industrial Systems

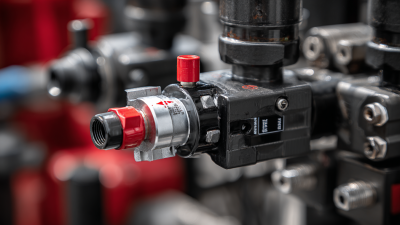

Hydraulic pressure control valves are vital components in modern industrial systems, functioning to maintain desired pressure levels and control fluid flow. These valves operate by regulating the pressure of hydraulic fluid within the system, ensuring that machinery operates efficiently and safely. When pressure rises beyond a pre-set level, the valve automatically adjusts to divert excess fluid or reduce flow, thereby preventing potential damage to equipment and maintaining operational integrity.

The mechanism of hydraulic pressure control valves often involves a combination of spring-loaded and pilot-operated designs, which allow for precise adjustments in response to varying loads and conditions. By receiving input from connected sensors, these valves can react quickly to changes in pressure, ensuring optimal performance in various applications such as manufacturing, construction, and energy production. This responsiveness not only improves efficiency but also enhances safety by mitigating the risks associated with overpressure scenarios. Therefore, understanding their functionality is crucial for engineers and operators who rely on hydraulic systems to achieve productivity and reliability in industrial processes.

Understanding the Importance of Hydraulic Pressure Control Valves in Modern Industrial Applications

| Feature | Function | Application | Advantages |

|---|---|---|---|

| Pressure Regulation | Maintains constant pressure in hydraulic systems | Manufacturing, Construction | Enhances system reliability and performance |

| Flow Control | Regulates fluid flow to different parts of the system | Automotive, Aerospace | Optimizes resource usage and energy efficiency |

| Safety Features | Prevents over-pressure situations through relief mechanisms | Oil & Gas, Power Plants | Reduces risk of equipment failure and safety hazards |

| Durability | Designed to withstand harsh operating conditions | Mining, Marine | Lowers maintenance costs and extends service life |

| Integration | Can be easily integrated into existing systems | Agricultural Machinery, Industrial Robots | Facilitates upgrades without complete system replacements |

Key Benefits of Utilizing Hydraulic Pressure Control Valves

Hydraulic pressure control valves are crucial components in modern industrial applications, providing precise regulation of fluid power while ensuring system safety and efficiency. One of the key benefits of utilizing these valves is their ability to enhance operational efficiency. According to a report by the International Society for Automation, effective hydraulic control can improve energy utilization by up to 30%, significantly reducing operational costs in heavy machinery and manufacturing processes.

Additionally, hydraulic pressure control valves play a vital role in safety management. By preventing overpressure scenarios, these valves protect both equipment and personnel, which is essential in high-stakes environments such as construction and petrochemical industries. The Fluid Power Journal highlights that systems equipped with advanced hydraulic control technologies can reduce the risk of hydraulic system failures by approximately 25%, emphasizing the importance of investing in reliable pressure control solutions for both longevity and safety in industrial operations.

Understanding the Importance of Hydraulic Pressure Control Valves

This chart showcases the key benefits of utilizing hydraulic pressure control valves in modern industrial applications, highlighting the efficiency and reliability they bring to various processes.

Step-by-Step Guide to Selecting the Right Pressure Control Valve

Choosing the right hydraulic pressure control valve is crucial for optimizing system performance in industrial applications. The first step in selecting a suitable valve is to determine the specific requirements of your fluid system. Consider factors such as the operating pressure range, flow capacity, and the type of fluid being controlled. Understanding these parameters will help narrow down the options available and ensure compatibility with your existing machinery.

Next, evaluate the valve type best suited for your application. Common types include pressure relief valves, pressure reducing valves, and sequence valves, each designed for particular functions within a hydraulic system. Additionally, assess material construction and sealing options to ensure durability and reliability under operating conditions. Finally, consult manufacturer's specifications and user reviews to gain insights into performance and maintenance requirements, ensuring that the selected valve not only meets current needs but is also adaptable for future modifications.

Maintenance Best Practices for Hydraulic Pressure Control Valves

Hydraulic pressure control valves play a crucial role in maintaining the efficiency and safety of hydraulic systems in various industrial applications. To ensure their optimal performance, regular maintenance is essential. One of the best practices involves conducting routine inspections to check for leaks, wear, and any signs of malfunction. These inspections should include examining the valve seals and fittings, as any degradation could lead to decreased system pressure and performance.

Another key maintenance practice is to keep the hydraulic fluid clean and free from contaminants. Dirty fluid can cause wear and tear on the valve components, leading to premature failure. Implementing a regular fluid replacement schedule and using filtration systems can significantly enhance the reliability of hydraulic pressure control valves. Additionally, operators should familiarize themselves with the specific manufacturer guidelines to ensure that adjustments and repairs are performed correctly, which can help extend the lifespan of the valves and prevent costly downtime in industrial operations.

Common Challenges and Solutions in Hydraulic Pressure Control Valve Applications

Hydraulic pressure control valves are critical components in various industrial applications, ensuring the efficient operation of hydraulic systems. However, the effective implementation of these valves is often hindered by several challenges. One significant issue is pressure fluctuations, which can arise due to changes in load conditions or system design. According to a report by MarketsandMarkets, the global hydraulic valves market is projected to grow from $29.9 billion in 2020 to $39.3 billion by 2025, highlighting the increasing reliance on hydraulic systems and the necessity for robust pressure control solutions.

Another challenge involves the maintenance and troubleshooting of hydraulic pressure control valves. Frequent wear and tear can lead to valve failures, resulting in system downtime and increased operational costs. The International Society of Automation (ISA) indicates that maintenance costs can account for about 30-40% of the total operational expenses in many industrial sectors. Implementing predictive maintenance strategies, backed by real-time monitoring and condition-based assessments, can significantly mitigate these issues. By adopting advanced monitoring technologies, industries can enhance the reliability of hydraulic systems and reduce unplanned outages associated with pressure control valve malfunctions.

Related Posts

-

Exploring the Benefits of Advanced Hydraulic Directional Valves for Efficient Fluid Control

-

Understanding the Role of Hydraulic Valves in Modern Industrial Applications

-

Maximizing Efficiency: How Directional Control Valves Transform Hydraulic Systems

-

Unlocking Efficiency: The Vital Role of Hydraulic Pressure Relief Valves in Industrial Systems

-

Exploring Innovative Control Products: Transforming Industries with Smart Technology

-

The Essential Guide to Understanding Hydraulic Power Packs in Industrial Applications