- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

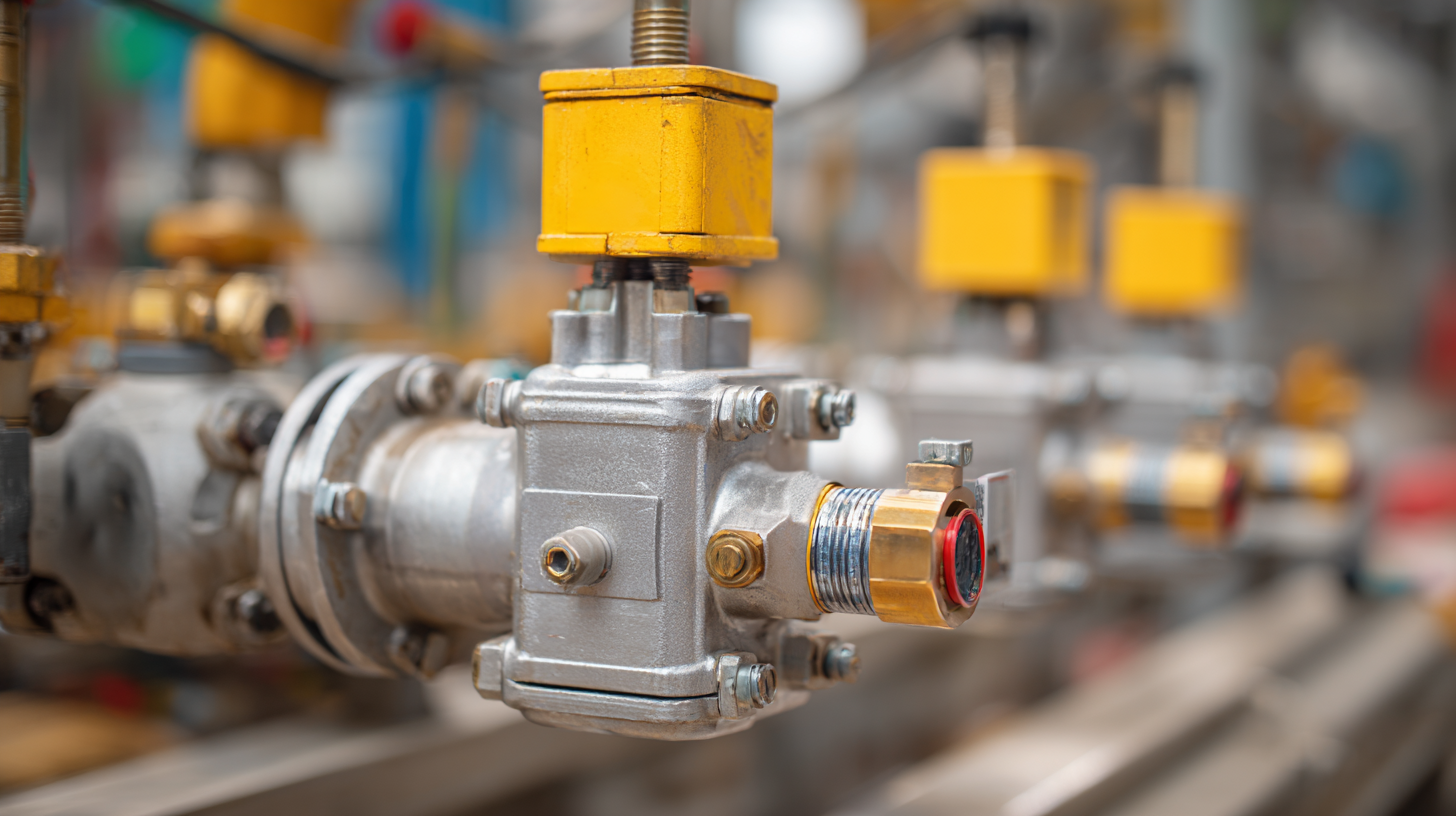

Understanding the Importance of Hydraulic Flow Control Valves in Modern Industrial Applications

In the ever-evolving landscape of modern industry, hydraulic systems serve as the backbone for a wide array of applications, ranging from manufacturing to construction. Central to the efficiency and reliability of these systems is the hydraulic flow control valve, a critical component that governs the flow and pressure of hydraulic fluids. According to a report by MarketsandMarkets, the global hydraulic valves market is expected to reach USD 41 billion by 2025, driven by increasing automation and the demand for precision in industrial processes.

The hydraulic flow control valve plays an essential role in optimizing performance, enabling operators to adjust and maintain desired flow rates and pressures, which ultimately enhances productivity and equipment longevity. Data from a recent survey indicates that nearly 70% of manufacturing firms are investing in advanced hydraulic controls to meet the increasing need for energy efficiency and reduced operational costs. As industries grapple with challenges such as fluctuating energy prices and the need for sustainable practices, the importance of hydraulic flow control valves cannot be overstated. These devices not only improve operational efficiency but also contribute to the overall safety and environmental compliance of hydraulic systems, making them vital in today's industrial applications.

Table of Contents

[Hide]

Key Functions of Hydraulic Flow Control Valves in Industrial Settings

Hydraulic flow control valves play a crucial role in optimizing the performance of hydraulic systems across various industrial applications. By managing the flow rate and pressure within hydraulic circuits, these valves ensure that machinery operates efficiently and reliably. According to a report by the International Fluid Power Society, nearly 86% of industrial applications utilizing hydraulic systems benefit from the precision flow control that these valves provide. This precision not only enhances operational performance but also extends the lifespan of hydraulic components by preventing excessive pressure that can lead to wear and tear.

One of the key functions of hydraulic flow control valves is adjusting the speed of actuators. By controlling the rate at which hydraulic fluid is allowed to flow into cylinders or motors, these valves enable smooth and consistent movement in machinery. A study highlighted in the Journal of Hydraulic Engineering notes that proper flow control can improve response times in automated systems by up to 40%, allowing industries to achieve higher productivity levels. Moreover, effective flow control assists in energy conservation, as systems perform optimally without unnecessary fluid loss, thus minimizing operational costs in an era where energy efficiency is becoming increasingly critical.

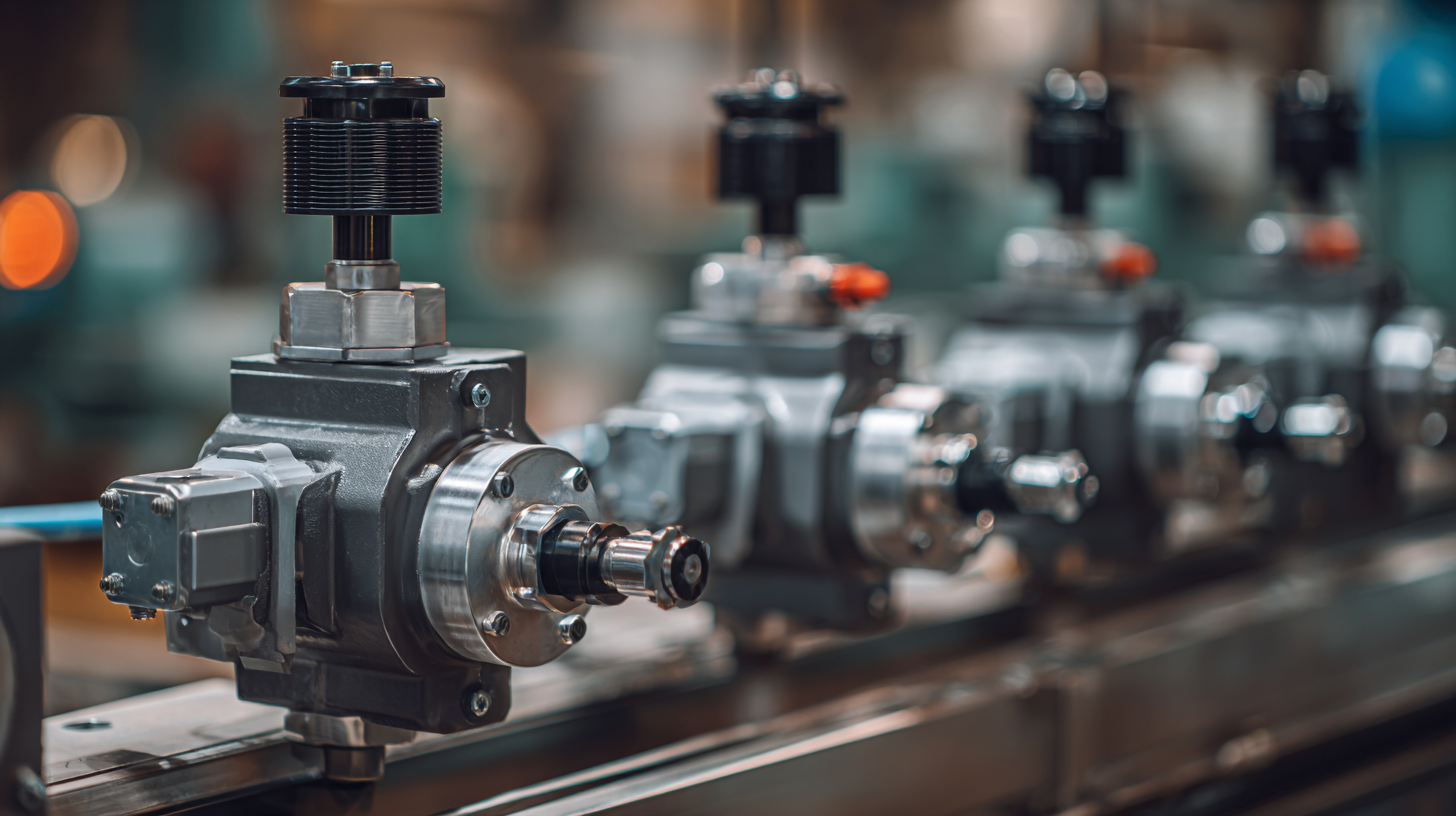

Types of Hydraulic Flow Control Valves and Their Specific Applications

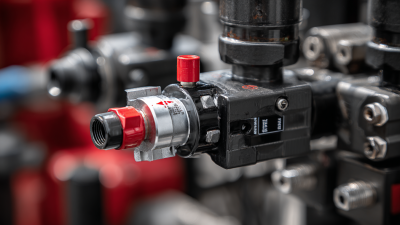

Hydraulic flow control valves are essential components in various industrial applications as they regulate fluid flow and pressure. There are several types of hydraulic flow control valves, each designed for specific functions and operational requirements. The most common types include throttle valves, pressure-reducing valves, and flow regulators. Throttle valves adjust the flow rate and are typically used in systems where consistent speed control of actuators is necessary.

Pressure-reducing valves are critical in maintaining safe operating conditions by regulating output pressure to levels that are appropriate for the downstream hydraulic components. In contrast, flow regulators ensure a steady flow rate regardless of variations in upstream pressure or demand from the hydraulic circuit. These specialized valves find applications across various industries, including manufacturing, construction, and automotive, where they enhance efficiency and reliability in fluid power systems, enabling precise control over machinery and processes. By selecting the appropriate type of flow control valve, industries can achieve optimal performance and safety in their hydraulic systems.

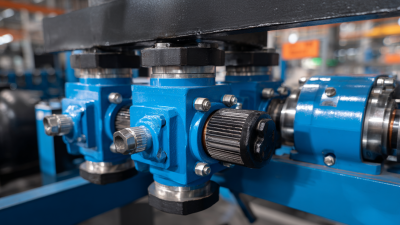

Advantages of Utilizing Hydraulic Flow Control Valves in Automation

Hydraulic flow control valves play a crucial role in enhancing the efficiency and precision of industrial automation systems. According to a report by MarketsandMarkets, the global hydraulic valves market is projected to grow from USD 2.67 billion in 2020 to USD 3.79 billion by 2025, highlighting the increasing reliance on such components in various sectors. One of the key advantages of utilizing hydraulic flow control valves is their ability to regulate the speed of actuators, ensuring consistent motion and preventing abrupt stops that can lead to mechanical wear and increased downtime.

Hydraulic flow control valves play a crucial role in enhancing the efficiency and precision of industrial automation systems. According to a report by MarketsandMarkets, the global hydraulic valves market is projected to grow from USD 2.67 billion in 2020 to USD 3.79 billion by 2025, highlighting the increasing reliance on such components in various sectors. One of the key advantages of utilizing hydraulic flow control valves is their ability to regulate the speed of actuators, ensuring consistent motion and preventing abrupt stops that can lead to mechanical wear and increased downtime.

Moreover, the integration of advanced hydraulic flow control valves in automation is recognized for its capacity to reduce energy consumption significantly. A study by the International Energy Agency suggests that optimizing hydraulic systems can result in energy savings of up to 30%, making operations not only more cost-effective but also environmentally sustainable. By allowing precise control over fluid dynamics, these valves facilitate smoother operations, improved cycle times, and enhanced overall system responsiveness, which are essential for modern manufacturing processes. As industries continue to embrace automation, the strategic implementation of hydraulic flow control valves will undoubtedly become a linchpin in achieving operational excellence.

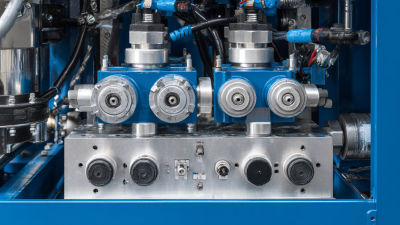

Best Practices for Maintenance and Troubleshooting of Flow Control Valves

Hydraulic flow control valves are essential components in modern industrial systems, managing the flow of liquids and ensuring optimal performance of machinery. To maintain their effectiveness, regular maintenance and troubleshooting are crucial. A well-implemented maintenance schedule can prolong the lifespan of these valves, improving system efficiency and reducing downtime. Operators should routinely check for signs of leaks, wear, or damage, as these conditions can severely impact the hydraulic system's performance.

When troubleshooting flow control valves, it's important to understand the common issues that can arise. Problems such as fluctuating flow rates or unresponsive valves may indicate the need for adjustments or replacements. Operators should familiarize themselves with the operational parameters and correct any identified discrepancies promptly. Additionally, keeping detailed maintenance records can help identify patterns and potential future issues, ensuring the hydraulic system continues to function smoothly in demanding industrial environments.

Understanding the Importance of Hydraulic Flow Control Valves in Modern Industrial Applications - Best Practices for Maintenance and Troubleshooting of Flow Control Valves

| Aspect | Description | Best Practices | Common Issues | Troubleshooting Steps |

|---|---|---|---|---|

| Function | Regulates flow of hydraulic fluid to ensure efficiency and safety | Regular inspection and calibration | Inconsistent flow rates | Check valve adjustments and seals |

| Types | Includes pressure control, flow control, and proportional valves | Understand each type's specific use case | Valve leaks | Inspect seals and connections, replace as needed |

| Maintenance Frequency | Recommended every 6 months or based on usage | Document maintenance activities | Unresponsive valve adjustments | Re-calibrate the actuator and verify inputs |

| Installation Considerations | Proper orientation and alignment are crucial | Follow manufacturer's specifications for installation | Noise during operation | Check for cavitation, and ensure fluid is filtered |

Future Trends in Hydraulic Flow Control Technology for Industry 4.0

The evolution of hydraulic flow control technology is pivotal as industries move towards Industry 4.0, where automation, data exchange, and smart manufacturing systems dominate. According to a recent report by the International Society for Automation, the global market for hydraulic components, particularly flow control valves, is projected to grow at a CAGR of 5.1% through 2027. This growth emphasizes the increasing need for precision control in hydraulic systems, essential for enhancing productivity and operational efficiency.

Emerging technologies such as IoT and machine learning are transforming hydraulic systems by enabling real-time monitoring and predictive maintenance. For instance, by integrating smart sensors within hydraulic flow control valves, manufacturers can optimize fluid dynamics and minimize energy consumption. A study by MarketsandMarkets forecasts that the IoT in industrial hydraulics will reach a market size of $1.7 billion by 2026, underscoring the trend towards smarter, more interconnected systems. These advancements not only reduce downtime but also improve the overall reliability of hydraulic operations, making flow control valves a crucial component in the future of industrial automation.

Related Posts

-

Understanding the Importance of Hydraulic Pressure Control Valves in Modern Industrial Applications

-

Exploring the Benefits of Advanced Hydraulic Directional Valves for Efficient Fluid Control

-

Understanding the Role of Hydraulic Valves in Modern Industrial Applications

-

Exploring the Benefits of Yuken Directional Valves for Enhanced Hydraulic Performance

-

The Essential Guide to Understanding Hydraulic Power Packs in Industrial Applications

-

Maximizing Efficiency: How Directional Control Valves Transform Hydraulic Systems