- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

Why Is Hydraulic Equipment Essential in Modern Industry?

Hydraulic equipment plays a pivotal role in modern industry, serving as the backbone of various manufacturing and construction processes. According to a report by the International Federation of Robotics, nearly 90% of industrial robots utilized in factories are powered by hydraulic systems, highlighting their critical function in enhancing operational efficiency and precision. Furthermore, the global hydraulic equipment market is expected to reach approximately $55 billion by 2026, growing at a compound annual growth rate (CAGR) of around 5.5%. This surge underscores the increasing reliance on hydraulic technology to meet the demands of automation and productivity across multiple sectors.

The versatility of hydraulic equipment is evident in its widespread applications, ranging from excavation and lifting in construction to precision operations in machinery manufacturing. A study by the National Fluid Power Association indicates that hydraulic systems can deliver more power with less energy compared to their pneumatic counterparts, making them essential for industries aiming to enhance energy efficiency and reduce operational costs. As companies strive to innovate and optimize their workflows, the demand for hydraulic solutions is set to escalate, affirming their essential status in the industrial landscape.

Table of Contents

[Hide]

The Role of Hydraulic Equipment in Enhancing Industrial Efficiency

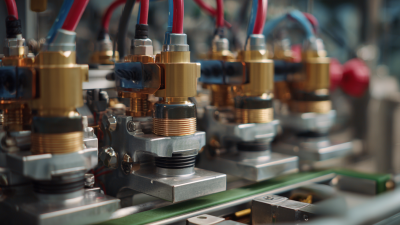

Hydraulic equipment plays a pivotal role in enhancing industrial efficiency across various sectors by providing powerful, precise, and reliable motion control solutions. This technology utilizes pressurized fluids to generate mechanical power, making it ideal for heavy lifting and equipment operation in warehouses, construction sites, and manufacturing facilities. The ability of hydraulic systems to transmit large amounts of energy through relatively compact units allows industries to optimize their space and increase workload capabilities without compromising performance.

Moreover, hydraulic equipment contributes to improved operational speed and productivity. With the ability to quickly activate and deactivate machinery, hydraulic systems minimize downtime and streamline processes. For example, in manufacturing plants, hydraulic presses and lifts enable rapid production cycles and facilitate quick adjustments between tasks. This dynamic responsiveness not only boosts throughput but also enhances flexibility, allowing companies to adapt swiftly to changing demands and optimize resource allocation. Consequently, industries that leverage hydraulic technology gain a considerable competitive edge in today’s fast-paced marketplace.

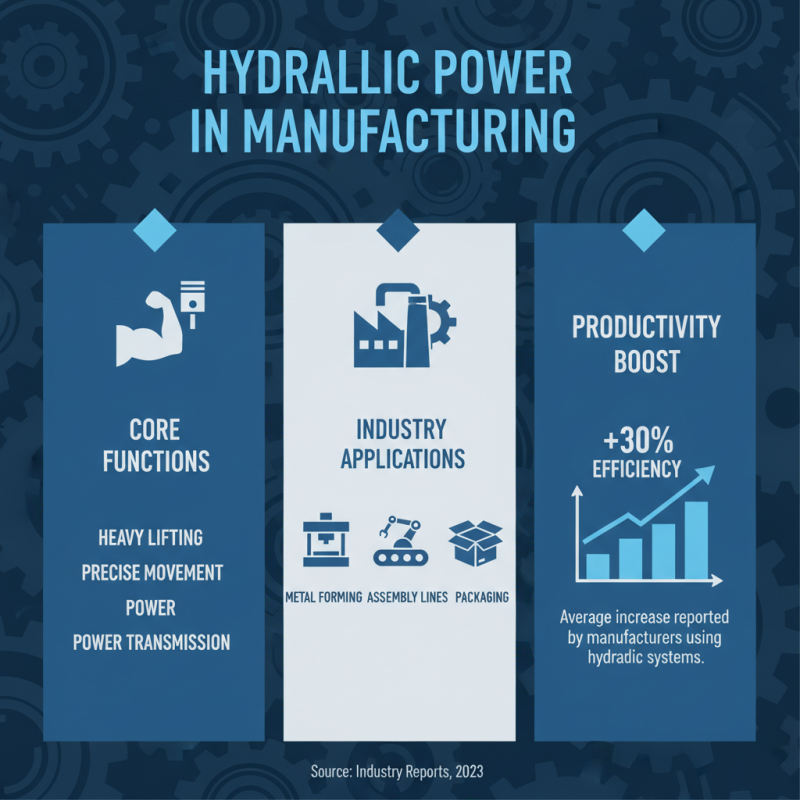

Hydraulic Equipment Usage and Efficiency in Modern Industry

This chart represents the percentage of different industrial sectors utilizing hydraulic equipment and the corresponding efficiency gains observed.

Key Industries Benefiting from Hydraulic Technology: A Statistical Overview

Hydraulic technology plays a crucial role in various industries, facilitating processes that involve heavy lifting, precise movement, and the transmission of power. The manufacturing sector is one of the most significant beneficiaries of hydraulic systems, utilizing hydraulic presses and lifts for tasks such as metal forming, assembly, and packaging. Statistics indicate that hydraulic equipment accounts for a substantial portion of the operational efficiency in factories, with many manufacturers reporting productivity increases of over 30% when incorporating hydraulic mechanisms into their processes.

Additionally, the construction industry heavily relies on hydraulic technology for equipment like excavators, bulldozers, and cranes. Hydraulic systems allow for the powerful and precise operation of heavy machinery, enabling construction teams to perform complex tasks on-site. Reports suggest that projects equipped with hydraulic machinery are completed up to 25% faster compared to those that do not use this technology. Other sectors, including agriculture and aerospace, also leverage hydraulic systems to enhance efficiency and performance, demonstrating the widespread importance of hydraulic equipment across modern industry.

Comparative Analysis of Hydraulic Systems vs. Electric Drives in Manufacturing

Hydraulic systems and electric drives are both pivotal in modern manufacturing, each with distinct advantages that influence their application in various industrial contexts. According to a report by the International Society for Automation, hydraulic systems represent approximately 25% of the power used in manufacturing plants. They are renowned for their ability to provide high levels of force and torque in compact designs, making them ideal for heavy lifting and precise control operations. This efficiency is particularly evident in industries like automotive and aerospace, where hydraulic presses and actuators are essential for assembling and shaping components.

On the other hand, electric drives have seen a significant increase in adoption, largely due to advancements in technology that improve their energy efficiency and precision. A study by the U.S. Department of Energy reveals that electric drives can achieve energy savings of up to 30% compared to traditional hydraulic systems, especially in applications that require variable speed operation. This has led many manufacturers to pivot towards electric options for their versatility and lower maintenance costs. Ultimately, the choice between hydraulic systems and electric drives hinges on the specific needs of the application, with both systems continuously evolving to meet the demands of modern industry.

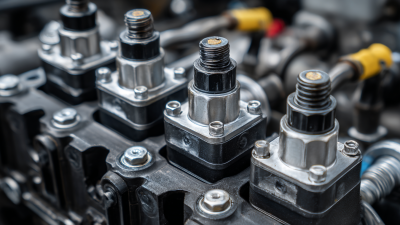

Safety and Maintenance Standards for Hydraulic Equipment in Modern Industry

Hydraulic equipment plays a pivotal role in modern industry, but ensuring its safe operation and maintenance is equally important. Safety standards for hydraulic systems are essential to prevent accidents and injuries in the workplace. These standards typically encompass the design, installation, and operation of hydraulic systems, emphasizing the need for regular inspections and adherence to established safety protocols. Operators must be trained to recognize potential hazards and implement measures to mitigate risks, such as using personal protective equipment (PPE) and ensuring proper equipment operation.

In addition to safety, maintenance standards are critical to prolonging the lifespan of hydraulic equipment. Regular maintenance checks, including fluid level assessments and leakage inspections, help identify issues before they escalate into more significant problems. The use of high-quality hydraulic fluids and components can enhance the system's reliability and performance. Establishing a structured maintenance schedule allows for timely interventions and reduces downtime, ensuring smooth operation in the often fast-paced industrial environments. By adhering to these safety and maintenance standards, industries can optimize their hydraulic systems while fostering a safer workplace for their employees.

Future Trends: Innovations in Hydraulic Technology for Industry 4.0

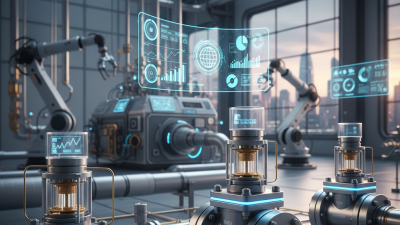

The rapid evolution of Industry 4.0 has set the stage for groundbreaking innovations in hydraulic technology, making it a crucial element in modern industrial applications. As the demand for automation and smart systems increases, hydraulic equipment has adapted by integrating advanced sensors and IoT connectivity. These enhancements allow for real-time monitoring and data analysis, which significantly improve operational efficiency and predictive maintenance practices. This shift not only reduces downtime but also optimizes energy consumption, aligning hydraulic systems with sustainable manufacturing goals.

Future trends in hydraulic technology also emphasize the development of more compact and versatile hydraulic systems. With the emergence of smaller, more powerful actuators and pumps, industries can design more efficient machinery without sacrificing performance. Furthermore, advancements in fluid power systems, such as the integration of artificial intelligence, promise to revolutionize how hydraulic systems are controlled and operated. By enabling smarter decision-making and automated adjustments, these innovations enhance productivity and ensure a seamless transition towards a fully automated manufacturing environment.

Why Is Hydraulic Equipment Essential in Modern Industry? - Future Trends: Innovations in Hydraulic Technology for Industry 4.0

| Dimension | Description | Current Trends | Future Innovations |

|---|---|---|---|

| Efficiency | Hydraulic systems provide high power density, allowing for reduced energy consumption. | Integration of IoT for real-time monitoring and efficiency improvement. | Use of AI to optimize hydraulic system performance and predictive maintenance. |

| Versatility | Applicable in various industries like construction, manufacturing, and automotive. | Customization of hydraulic equipment for specific applications. | Modular designs allowing rapid reconfiguration for new tasks. |

| Safety | Modern hydraulic systems are designed with safety features to prevent leaks and failures. | Enhanced sensor systems for immediate fault detection. | Development of fail-safe systems that automatically handle system overloads. |

| Environmental Impact | Hydraulic equipment traditionally has a significant environmental footprint due to fluid leakage. | Increased use of biodegradable hydraulic fluids. | Research into closed-loop hydraulic systems to minimize environmental effects. |

| Cost-Effectiveness | Initial investment is high, but operational costs can be low due to efficiency. | Focus on lifecycle cost analysis for better investment decisions. | Predictive analytics to optimize maintenance schedules and reduce unexpected repair costs. |

Related Posts

-

7 Essential Tips for Mastering Hydraulic Controls in Your Projects

-

Exploring the Benefits of Yuken Directional Valves for Enhanced Hydraulic Performance

-

2025 Top 10 Check Valves Trends Innovations and Market Statistics

-

Understanding Yuken Directional Valves and Their Applications in Modern Hydraulic Systems

-

The Future of Automation: How Servo Valves are Revolutionizing Industry Efficiency

-

Understanding the Importance of Hydraulic Flow Control Valves in Modern Industrial Applications