- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

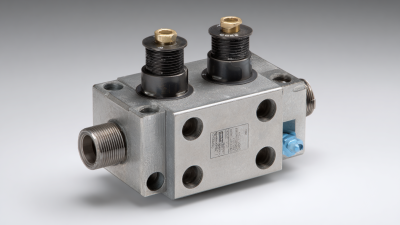

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

10 Essential Tips for Maintaining an Efficient Hydraulic System

In the realm of industrial machinery, ensuring the optimal performance of a hydraulic system is essential for productivity and safety. Renowned hydraulic systems expert, Dr. Emily Santos, emphasizes this by stating, "A well-maintained hydraulic system is not just a component of operational efficiency; it is the backbone of reliability in any heavy machinery." This insight highlights the critical role that maintenance plays in the longevity and functionality of hydraulic systems across various industries.

As these systems are integral to numerous applications—from construction equipment to aviation technologies—their proper upkeep cannot be overstated. Neglecting maintenance can lead to costly downtimes and increased operational risks. Therefore, understanding the essential practices for maintaining an efficient hydraulic system is vital for any operation reliant on hydraulic technology. In the following sections, we will explore ten indispensable tips that can help ensure your hydraulic system remains in peak condition, minimizing the risks of failure and enhancing overall productivity.

Table of Contents

[Hide]

10 Key Components of a Hydraulic System and Their Functions

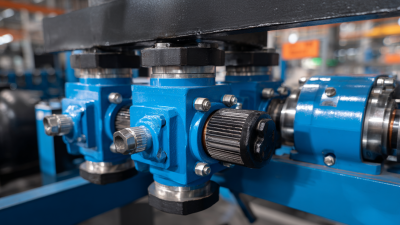

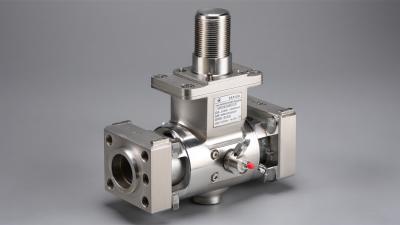

A hydraulic system is comprised of several key components, each playing a crucial role in its overall efficiency and functionality. The primary component is the hydraulic pump, which converts mechanical energy into hydraulic energy, generating fluid flow to power the system. Next, we have hydraulic cylinders, which utilize this fluid pressure to create linear motion, enabling machinery to perform tasks with great force and precision. Additionally, hydraulic motors are responsible for converting hydraulic pressure back into mechanical energy, driving various equipment and machinery.

Other essential components include valves, which control the direction and flow of hydraulic fluid within the system. They ensure that the right amount of pressure is directed to the appropriate areas, thus maintaining optimal operation. Hydraulic hoses and pipes transport the fluid between components, and it is crucial that they are durable and leak-free to prevent system failures.

Finally, a hydraulic reservoir holds the fluid, allowing for expansion and compensation for leaks while also helping in the cooling and contamination control of the fluid. Understanding these ten key components and their functions is vital for anyone looking to maintain an efficient hydraulic system.

Understanding Fluid Properties and Their Impact on System Efficiency

Understanding the fluid properties within a hydraulic system is crucial for achieving optimal efficiency. The selection of hydraulic fluid significantly impacts not only the system's performance but also its longevity. Important characteristics such as viscosity, density, and temperature stability play a vital role. For example, the viscosity of the fluid influences the ease with which it can be pumped through the system; too high a viscosity can result in increased friction and energy loss, while too low a viscosity may lead to inadequate lubrication and potential system failures.

Moreover, the additives present in hydraulic fluids can enhance performance by improving lubrication and preventing corrosion. These additives can also help minimize foaming and oxidation, which are critical for maintaining fluid integrity over time. Understanding how temperature affects fluid properties is another essential factor. Hydraulic systems often operate under varying temperatures, and fluctuations can lead to changes in fluid viscosity. Regular monitoring and adjustment of the fluid based on temperature can ensure that the hydraulic system operates efficiently, reducing the risk of malfunctions and prolonging equipment life.

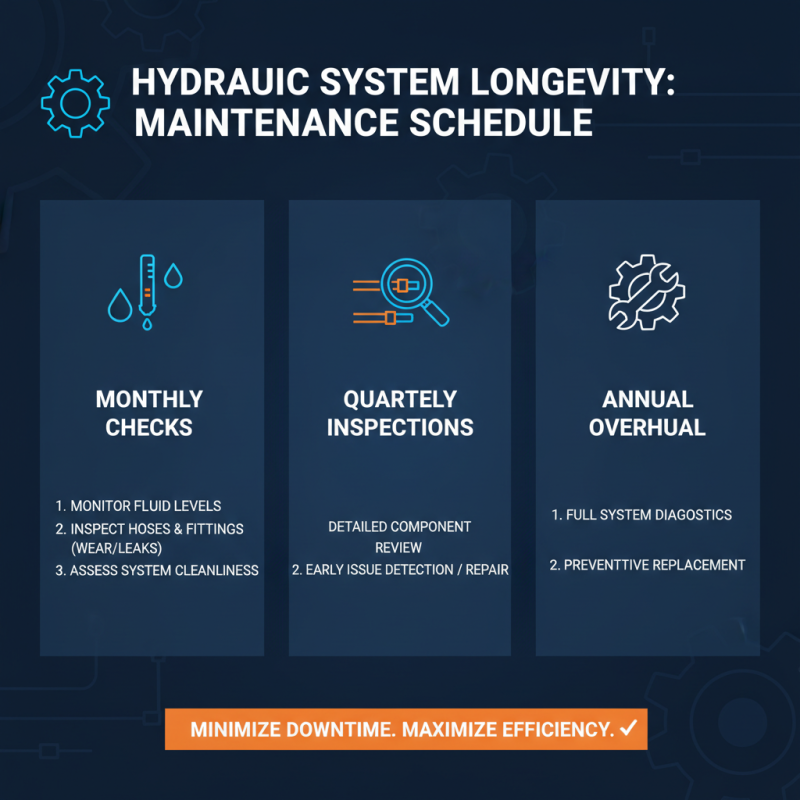

Regular Maintenance Schedules: Best Practices for Hydraulic Systems

Establishing a regular maintenance schedule is crucial for ensuring the longevity and efficiency of hydraulic systems. Regular checks should include monitoring fluid levels, inspecting hoses and fittings for wear, and assessing the overall cleanliness of the system. Scheduled inspections help identify potential issues before they escalate, allowing for timely repairs and minimizing downtime. It’s advisable to create a detailed checklist that outlines what to inspect during each maintenance visit, ensuring nothing is overlooked.

In addition to routine checks, fluid analysis should be part of the maintenance plan. By routinely analyzing the hydraulic fluid, operators can detect changes in fluid properties that may indicate contamination or degradation. Implementing a strict fluid replacement schedule based on the manufacturer’s recommendations further enhances system reliability. Furthermore, training personnel on best practices for maintaining hydraulic systems is essential. Proper training ensures that those responsible for upkeep understand how to perform routine checks and recognize signs of trouble, ultimately fostering a proactive approach to hydraulic maintenance.

Diagnosing Common Hydraulic System Issues Using Industry Standards

Diagnosing common hydraulic system issues is pivotal for ensuring the efficiency and longevity of the machinery. By adhering to industry standards, operators can effectively pinpoint problems before they escalate into costly repairs. Common symptoms such as unusual noises, fluctuations in pressure, or leaks often signal underlying issues. Utilizing diagnostic tools like pressure gauges and flow meters, technicians can accurately assess system performance, helping to identify whether the root cause stems from hydraulic fluid contamination, worn seals, or inadequate maintenance practices.

Furthermore, routine inspections based on established guidelines can enhance system reliability. Checks should include fluid levels, filter conditions, and the integrity of hoses and fittings. Implementing a structured maintenance schedule not only addresses immediate concerns but also mitigates future risks, promoting a proactive rather than reactive approach. By fostering an understanding of these diagnostic standards, operators are better equipped to maintain an efficient hydraulic system, ultimately leading to improved operational excellence and reduced downtime.

The Importance of Hydraulic Fluid Quality and Its Performance Metrics

The quality of hydraulic fluid is a crucial factor that directly influences the performance and longevity of hydraulic systems. According to a study by the Hydraulic Institute, nearly 70% of hydraulic system failures can be traced back to inadequate fluid quality. The properties of hydraulic fluid, including viscosity, thermal stability, and contamination level, play a significant role in ensuring optimal system efficiency. Regular monitoring of these performance metrics is essential to prevent potential breakdowns and maintain operational effectiveness.

Tip: Periodically assess the viscosity indices of your hydraulic fluids to ensure they remain within the recommended range, as this can directly affect system responsiveness and energy consumption. Maintaining proper fluid levels not only aids in efficient operation but also prevents overheating, which can degrade fluid quality over time.

Additionally, contamination is a prevalent issue that can compromise hydraulic fluid quality. A report by the National Fluid Power Association suggests that up to 90% of hydraulic system failures are caused by contaminants such as dirt, water, and metal particles. Implementing regular filtration and fluid replacement schedules can significantly reduce the risk of contamination and enhance system reliability.

Tip: Consider using advanced filtration systems to capture microscopic particles which can lead to pump wear and decreased efficiency. A proactive approach to fluid management will allow operators to sustain peak performance levels while minimizing maintenance costs.

Related Posts

-

Top Trends in 2025 for Check Valves You Need to Know About

-

Understanding the Importance of Hydraulic Pressure Control Valves in Modern Industrial Applications

-

Why Hydraulic Flow Control Valves are Essential for Optimizing System Performance: Insights and Data

-

What is a Pilot Operated Check Valve and How Does It Work in Hydraulic Systems

-

7 Essential Tips for Mastering Hydraulic Controls in Your Projects

-

How to Choose the Right Directional Control Valve for Your Project