- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

7 Essential Tips for Choosing the Right Hydraulic Valve for Your Application

When it comes to optimizing the performance and efficiency of hydraulic systems, choosing the right hydraulic valve is crucial. Whether you are designing a new system or upgrading an existing one, understanding the various types of hydraulic valves and their applications can make a significant difference in operational success. Hydraulic valves control the flow and pressure of fluids within hydraulic circuits, influencing everything from speed and force to smoothness of operation. With numerous options available in the market, selecting the appropriate hydraulic valve can be a daunting task.

By considering essential factors such as the valve's function, compatibility with other components, and environmental conditions, users can streamline their selection process. Each application may require specific characteristics, such as size, response time, and flow rate, emphasizing the need for careful evaluation. In this guide, we will outline seven essential tips that will help you navigate the complexities of hydraulic valve selection. These tips are designed to empower you with the knowledge to make informed decisions, ensuring that the hydraulic valves you choose will enhance the performance and reliability of your system.

Table of Contents

[Hide]

Understanding the Function and Types of Hydraulic Valves

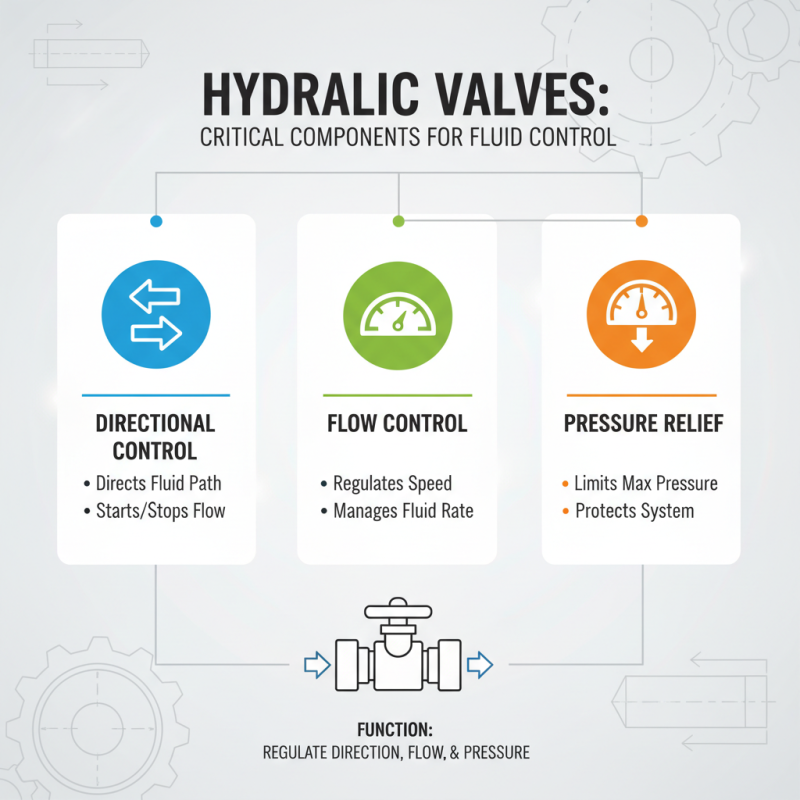

Hydraulic valves are critical components in hydraulic systems, directing fluid flow and controlling pressure to ensure efficient operation. Understanding their function is fundamental when selecting the right valve for your application. At their core, hydraulic valves regulate the direction, flow rate, and pressure of hydraulic fluid. They come in various types, including directional control valves, flow control valves, and pressure relief valves, each serving a specific purpose in the system.

Directional control valves determine the path of fluid movement within the hydraulic circuit, thereby controlling the actuator's movement. Flow control valves manage the speed of the fluid, affecting how quickly an actuator responds. Pressure relief valves are designed to prevent excessive pressure build-up, ensuring system safety. Familiarity with these types and their functions will help you make informed choices, allowing for optimal system performance tailored to your operational needs.

Identifying Key Application Requirements for Hydraulic Systems

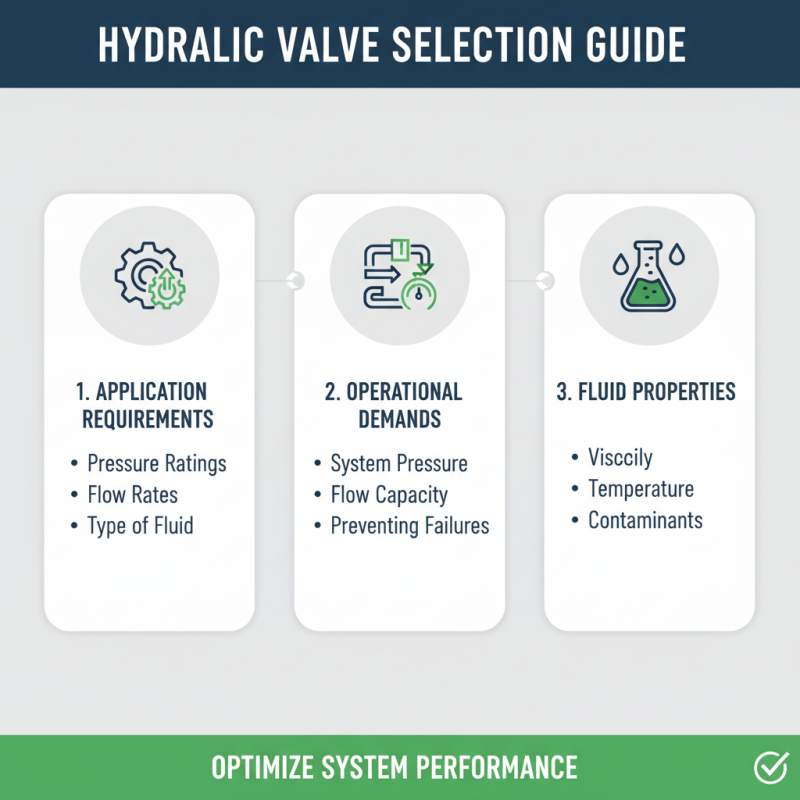

When selecting the right hydraulic valve for your system, understanding the specific application requirements is paramount. This involves analyzing several factors including pressure ratings, flow rates, and the type of fluid being used. Ensuring that the valve can handle the operational pressure and flow demand is critical; otherwise, performance issues may arise, leading to system inefficiencies or failures. Additionally, knowing the fluid properties—such as viscosity, temperature, and potential contaminants—helps in choosing a valve that can withstand the environmental conditions encountered in daily operations.

Another key aspect to consider is the operational environment where the hydraulic system will be utilized. Whether the system will be exposed to extreme temperature variations, corrosive substances, or high levels of dust and debris can influence the material and design of the valve needed. Furthermore, understanding the control mechanisms required for your application—whether manual, pneumatic, or electric—can help refine the selection process. By thoroughly assessing these application requirements, you can enhance the reliability and efficiency of your hydraulic system while minimizing maintenance costs and downtime.

Evaluating Performance Characteristics of Hydraulic Valves

When selecting the right hydraulic valve for your application, evaluating performance characteristics is crucial. One of the primary factors to consider is the flow rate, which determines how much fluid can pass through the valve. This directly impacts the efficiency of your hydraulic system. It's essential to match the valve's flow specifications with the demands of your machinery to avoid bottlenecks or excessive pressure drops that could hinder performance.

Another important characteristic to assess is the valve's pressure rating. The valve must withstand the maximum pressure of your system to ensure safety and reliability. Additionally, consider the valve’s response time and actuation type, as these factors influence how quickly the valve can respond to changes in system demands. A valve with a faster response time will improve the overall control and flexibility of the hydraulic system, which is particularly beneficial in applications that require rapid adjustments. By meticulously evaluating these performance characteristics, you can select a hydraulic valve that optimizes your application’s efficiency and longevity.

Considering Compatibility with Fluid Types and Pressure Levels

When selecting the right hydraulic valve for your application, understanding the compatibility with fluid types and pressure levels is crucial. Different fluids, such as oil, water, or specialized hydraulic fluids, can significantly impact the material selection for the valve. According to a report from the International Fluid Power Society, nearly 30% of hydraulic system failures are attributed to fluid compatibility issues. Therefore, it is vital to ensure that the valve materials are resistant to chemical reactions and degradation caused by the fluids in use.

Moreover, pressure levels play a critical role in valve functionality. Hydraulic systems often operate at varying pressure levels, which must be taken into account when choosing the appropriate valve. A study by the National Fluid Power Association indicates that more than 50% of hydraulic components fail due to incorrect pressure ratings. Selecting a valve that can handle the maximum pressure levels expected in the system not only enhances reliability but also extends the lifetime of both the valve and the entire hydraulic system. Ensuring compatibility with specific fluid types and accurately assessing operational pressure requirements are essential steps in optimizing hydraulic system performance.

Hydraulic Valve Selection: Pressure Ratings vs. Fluid Types

Assessing Manufacturer Reputation and Support Services

When selecting a hydraulic valve for your specific application, assessing the reputation of the manufacturer is crucial. A well-established manufacturer often indicates reliability and a history of producing quality products. Researching reviews and testimonials can provide valuable insights into their past performance and customer satisfaction. Additionally, consider the manufacturer’s experience in the industry, as seasoned companies are more likely to understand the intricacies of various applications and offer appropriate solutions.

Support services should also be a key factor in your decision-making process. Reliable customer support can significantly impact your experience, especially if complications arise or you require technical assistance. Evaluate whether the manufacturer offers comprehensive support options, such as customer service availability, technical advice, and after-sales services. A good manufacturer should provide detailed product documentation and training resources, ensuring you can efficiently integrate and maintain the hydraulic valve in your operations. Prioritizing these aspects will lead to a more informed and satisfactory purchase decision.

7 Essential Tips for Choosing the Right Hydraulic Valve for Your Application - Assessing Manufacturer Reputation and Support Services

| Criteria | Details | Importance Level |

|---|---|---|

| Manufacturer Experience | Look for manufacturers with a proven track record in producing hydraulic valves for your specific application. | High |

| Quality Certifications | Ensure the manufacturer has necessary quality certifications (e.g., ISO 9001). | High |

| Technical Support | Evaluate the availability of technical support for installation and troubleshooting. | Medium |

| Product Range | A manufacturer should offer a wide range of products suited to different applications. | Medium |

| Customer Reviews | Check customer feedback and reviews to gauge satisfaction and performance. | High |

| Innovation and Technology | Assess the manufacturer's commitment to innovation in hydraulic technology. | Medium |

| Warranty and Guarantees | Understand the warranty and service guarantees offered for the products. | High |

Related Posts

-

Understanding the Importance of Hydraulic Pressure Control Valves in Modern Industrial Applications

-

Exploring the Benefits of Advanced Hydraulic Directional Valves for Efficient Fluid Control

-

Understanding the Role of Hydraulic Valves in Modern Industrial Applications

-

How to Choose the Right Directional Control Valve for Your Project

-

Understanding the Importance of Hydraulic Flow Control Valves in Modern Industrial Applications

-

2025 Top Hydraulic Directional Valve Applications and Important Features to Know