- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

10 Essential Tips for Choosing the Right Hydraulic Relief Valve

Choosing the right hydraulic relief valve is crucial for maintaining system safety and efficiency. A hydraulic relief valve plays a vital role in preventing pressure build-up. It protects equipment and operators from potential hazards. However, selecting the right one can be challenging.

Consider factors like flow rate, response time, and the materials used. Different applications may require different specifications. High-pressure systems need reliable valves that can withstand extreme conditions. Inadequate choices can lead to failures, affecting productivity. Even small mistakes can have significant impacts on performance.

Investing time in research will yield better results. Consult with engineers or manufacturers for insights. Understand the specific requirements of your hydraulic system. Making informed choices is essential, yet many overlook this step. Reflect on past experiences and learn from them, to improve future decision-making.

Table of Contents

[Hide]

Understanding the Role of Hydraulic Relief Valves in Systems

Hydraulic relief valves play a critical role in maintaining system safety and performance. They protect hydraulic systems from excessive pressure, which can lead to catastrophic failures. According to data from the Fluid Power Society, nearly 30% of hydraulic system failures are directly linked to improper pressure regulation. This highlights the importance of choosing the right relief valve.

Selecting the appropriate valve involves understanding its set pressure, flow capacity, and response time. A valve that doesn’t react swiftly can cause system pressure to exceed safe limits. Interestingly, a study by the National Fluid Power Association found that up to 25% of hydraulic accidents could be prevented with the correct valve selection. Users often overlook specifications like pressure drop and fluid characteristics, which can lead to inefficiencies.

Moreover, proper maintenance is essential. Even the best valves will fail if they aren’t regularly inspected. Contaminants can clog valves, affecting their operation. Statistics show that 15% of valve-related failures were caused by poor maintenance practices. Users should reflect on their maintenance routines and consider how these might impact valve performance. This awareness can result in safer and more efficient hydraulic systems.

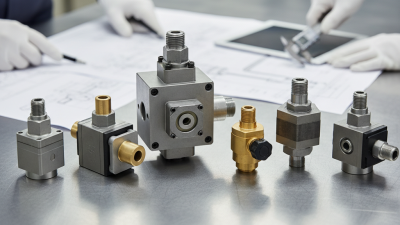

Key Specifications to Consider When Selecting a Hydraulic Relief Valve

When selecting a hydraulic relief valve, consider various specifications. The valve's maximum pressure setting is crucial. It determines how much pressure the valve can handle safely. Choose a valve that matches your system’s requirements. If it’s too low, it might lead to system failure.

Another important factor is the flow rate. Valves are rated for different flow capacities. Assess your hydraulic circuit's needs accurately. Too small of a valve will restrict flow and reduce efficiency. Look carefully at the pressure drop characteristics. This impacts how the valve responds under pressure changes.

Don't overlook the connection size and type. Compatibility with existing systems is vital. Incorrect sizes can cause leaks or failures. Lastly, consider the material. It should withstand the specific fluid types in your system. Selecting the right hydraulic relief valve is not a small task. It requires attention to detail and careful consideration of your unique application.

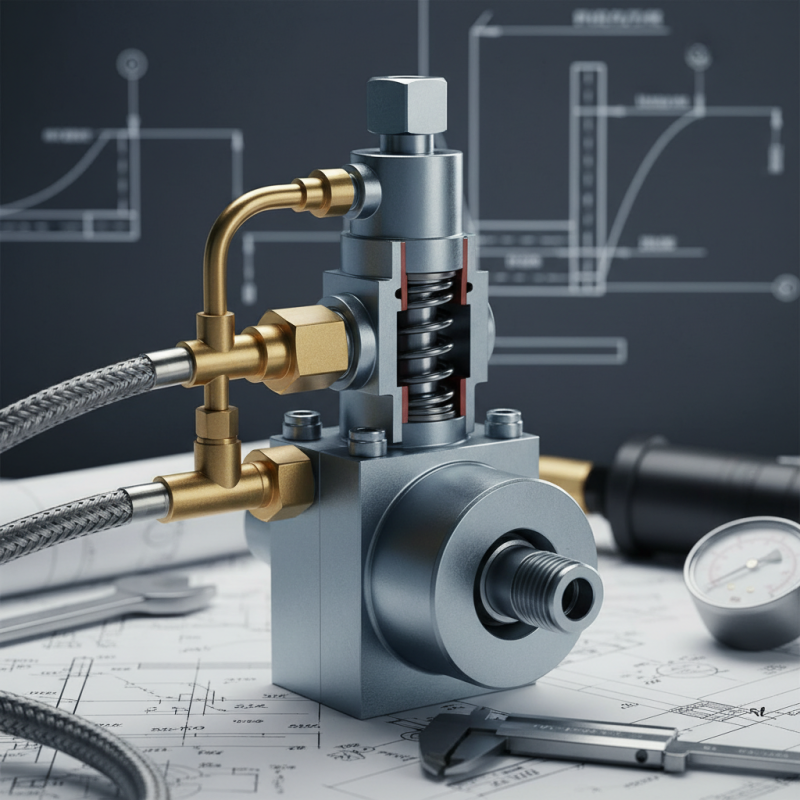

Different Types of Hydraulic Relief Valves and Their Applications

When selecting a hydraulic relief valve, understanding the different types is crucial. There are three main categories: direct acting, pilot operated, and adjustable relief valves. Each type serves a unique purpose and is used in various applications. Direct acting valves are compact and responsive. They are ideal for smaller systems needing quick pressure relief. However, they may not handle high flows effectively.

Pilot operated valves are commonly used in larger systems. They can manage higher flow rates and pressures. Their complex design, though, can be a challenge during maintenance. Adjustable relief valves offer flexibility, allowing users to set specific pressure levels. Yet, this adjustability may lead to user errors if not handled carefully.

In practice, the right choice depends on system requirements. Compatibility with other components is key. Many overlook the importance of accurate sizing and pressure settings. This oversight can result in inefficient operation or even system failure. It’s essential to consider how each type fits into the overall hydraulic system to ensure reliability and safety.

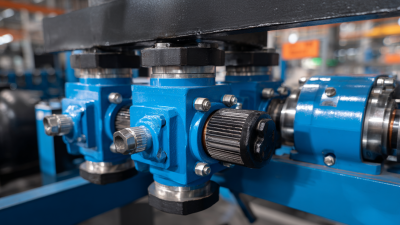

Factors Influencing the Performance of Hydraulic Relief Valves

When selecting a hydraulic relief valve, several factors can greatly influence its performance. One key aspect is the valve's setting pressure. Incorrect settings can lead to valve malfunction. If the pressure is too high, the system may experience dangerous surges. Conversely, a setting too low may fail to protect the system adequately. Understanding the specific needs of your hydraulic system is crucial.

Another factor is the valve's flow capacity. This affects how well it can divert excess fluid during peak conditions. If the flow capacity is insufficient, it may not relieve pressure effectively. Additionally, valve materials matter. The environment where the valve operates can lead to wear or corrosion. Using inappropriate materials can result in premature failure.

Lastly, consider the installation process. A poorly installed valve can cause leaks or performance issues. Take your time to review the installation requirements and ensure proper alignment. Reflect on past experiences. Have mistakes in the past shaped your approach today? Choosing the right hydraulic relief valve is not just about specifications; it's about understanding and learning from the nuances of your specific application.

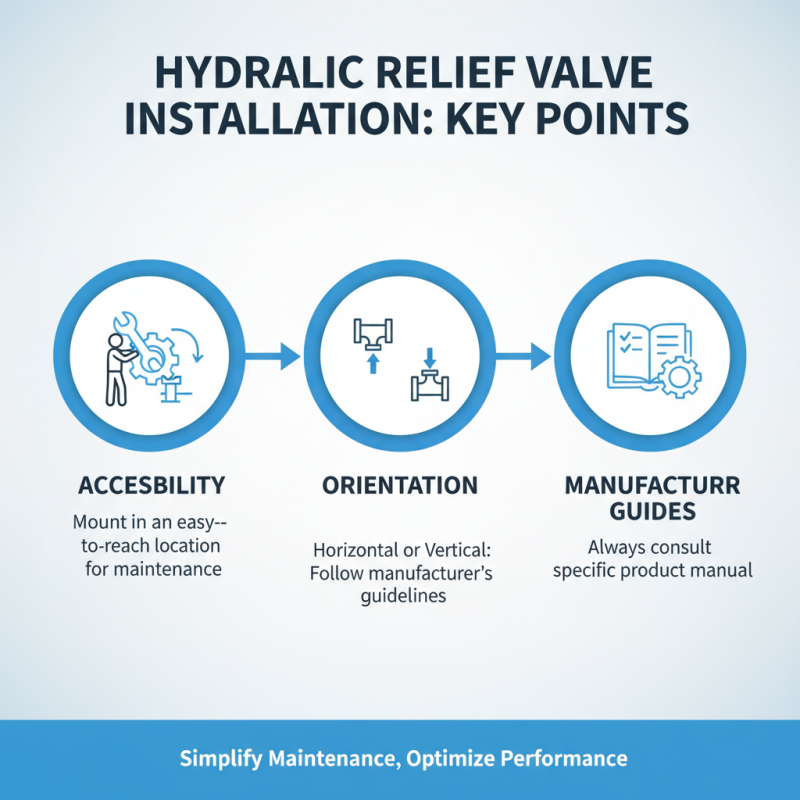

Best Practices for Installing and Maintaining Hydraulic Relief Valves

Installing hydraulic relief valves requires careful attention. Ensure that the valve is mounted in a location easy to access. This makes future maintenance simpler. Consider the orientation too. A horizontal or vertical installation may affect performance. Always follow the manufacturer’s guidelines.

Regular maintenance is crucial for optimum performance. Inspecting the valve periodically can help catch issues early. Check for leaks or unusual noises. These may indicate a problem. Also, clean the valve to prevent dirt buildup. Contaminants can affect its function and longevity.

Hydraulic systems operate under pressure. Sometimes, issues arise unexpectedly. Rushing installation may lead to mistakes. Take time to double-check connections. Verify that the pressure settings meet requirements. Learning from past installations helps avoid pitfalls. Assessing your work after installation can lead to better future practices.

Related Posts

-

Understanding the Importance of Hydraulic Pressure Control Valves in Modern Industrial Applications

-

7 Essential Tips for Choosing the Right Hydraulic Valve for Your Application

-

2026 Best Hydraulic Valve Innovations for Enhanced Performance?

-

Exploring the Benefits of Advanced Hydraulic Directional Valves for Efficient Fluid Control

-

Understanding the Importance of Hydraulic Flow Control Valves in Modern Industrial Applications

-

Understanding the Role of Hydraulic Valves in Modern Industrial Applications