- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

The Essential Guide to Understanding Hydraulic Power Packs in Industrial Applications

Hydraulic power packs are integral components in various industrial applications, providing reliable energy sources to equipment such as cranes, lifts, and manufacturing machinery. According to a report by MarketsandMarkets, the hydraulic power unit market is projected to reach USD 12 billion by 2025, growing at a CAGR of 5.5% from 2020. This growth is driven by the increased demand for automation in sectors like construction and agriculture, where hydraulic systems play a crucial role. Understanding the functionality and applications of hydraulic power packs is essential for optimizing performance and efficiency in industrial operations. As industries continue to evolve, the relevance of hydraulic power packs becomes more pronounced, making it imperative for professionals to stay informed about their capabilities and advancements to leverage them effectively in their operations.

Hydraulic power packs are integral components in various industrial applications, providing reliable energy sources to equipment such as cranes, lifts, and manufacturing machinery. According to a report by MarketsandMarkets, the hydraulic power unit market is projected to reach USD 12 billion by 2025, growing at a CAGR of 5.5% from 2020. This growth is driven by the increased demand for automation in sectors like construction and agriculture, where hydraulic systems play a crucial role. Understanding the functionality and applications of hydraulic power packs is essential for optimizing performance and efficiency in industrial operations. As industries continue to evolve, the relevance of hydraulic power packs becomes more pronounced, making it imperative for professionals to stay informed about their capabilities and advancements to leverage them effectively in their operations.

Table of Contents

[Hide]

Key Components of Hydraulic Power Packs in Industrial Settings

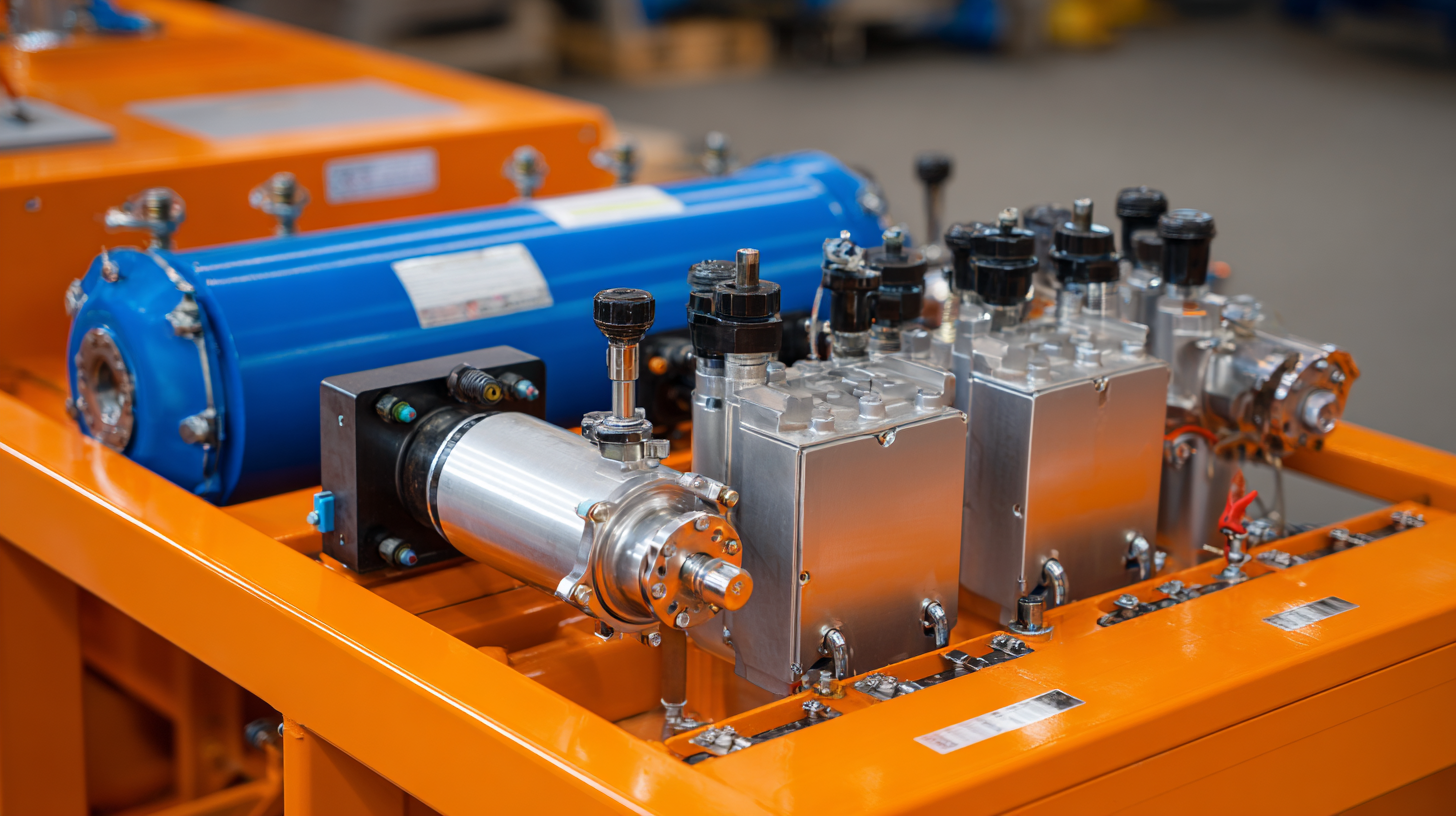

Hydraulic power packs are essential components in industrial applications, used to transfer power through pressurized hydraulic fluid. At the core of a hydraulic power pack are several critical components, including the hydraulic pump, reservoir, motor, and control valves. According to data from the International Fluid Power Society, hydraulic systems can deliver up to 90% efficiency, making them highly effective for heavy-duty applications such as lifting, loading, and moving materials within industries like construction and manufacturing.

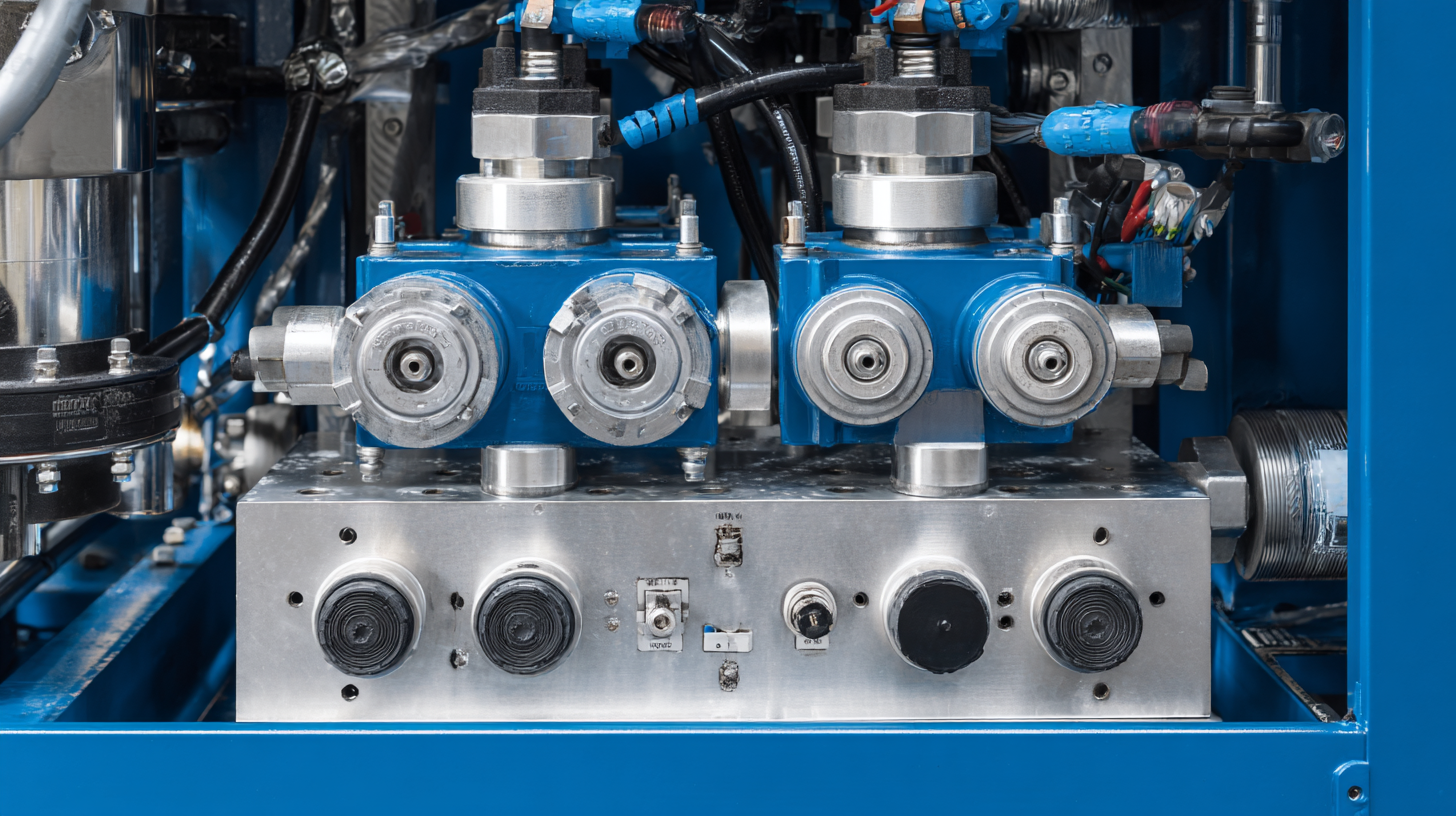

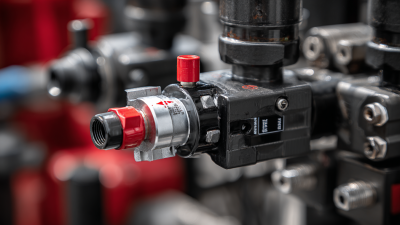

The hydraulic pump, often regarded as the heart of the power pack, is responsible for converting mechanical energy into hydraulic energy. Various types of pumps, such as gear, vane, or piston pumps, can be employed based on the required application. Additionally, the reservoir serves as the storage unit for hydraulic fluid, which not only acts as a medium for transferring power but also cools and filters the fluid. Control valves regulate the flow and pressure of hydraulic fluid, ensuring precise operation of machinery.

The market for hydraulic power packs is projected to grow significantly, with a report from MarketsandMarkets estimating a compound annual growth rate (CAGR) of 4.2% through 2026, driven by the increasing demand for automation in industrial setups.

Benefits of Utilizing Hydraulic Power Packs for Efficiency

Hydraulic power packs have become indispensable in industrial applications due to their efficiency and versatility. By utilizing hydraulic power packs, businesses can significantly enhance their operational efficiency. These systems are engineered to convert electrical energy into hydraulic energy, enabling powerful machinery to perform tasks with precision and speed. This not only boosts productivity but also reduces the need for manual labor, leading to safer and more streamlined operations.

**Tips for Maximizing Efficiency:**

1. **Regular Maintenance:** Conduct routine checks and maintenance on hydraulic power packs to ensure optimal performance and prevent downtime.

2. **Load Monitoring:** Implement load monitoring systems to avoid overloading, which can lead to equipment failure and increased costs.

Moreover, by harnessing the power of hydraulic systems, companies can optimize energy consumption and manage resources more effectively. This means lower operational costs and a reduced environmental footprint. The use of hydraulic power packs also allows for better control over various processes, giving operators the ability to adjust performance in real-time according to specific operational needs. This adaptability makes hydraulic systems invaluable in various industrial sectors, from manufacturing to construction.

Common Applications of Hydraulic Power Packs Across Industries

Hydraulic power packs are vital components in various industrial settings, providing the hydraulic energy necessary for the operation of multiple machinery and equipment. One of the most common applications of hydraulic power packs is in construction, where they drive heavy equipment such as excavators, lifts, and hydraulic hammers. These power packs facilitate tasks that require significant force, ensuring efficiency and productivity on job sites.

In manufacturing, hydraulic power packs play a crucial role in automation and material handling. They are often used to power presses, conveyors, and robotic arms, enabling precise movement and control over manufacturing processes. The ability to easily regulate pressure allows for superior flexibility and adaptability in production lines.

**Tips:** When selecting a hydraulic power pack for your application, consider factors such as flow rate, pressure requirements, and energy efficiency. Regular maintenance can also enhance the longevity and performance of your hydraulic systems. Always ensure safety protocols are in place, as hydraulic systems can pose risks if not handled properly.

Maintenance Practices for Optimal Performance of Hydraulic Systems

Proper maintenance practices are crucial for the optimal performance of hydraulic systems, particularly in industrial applications where efficiency and reliability are paramount. According to a report by the International Society of Automation (ISA), nearly 30% of hydraulic system failures are attributed to inadequate maintenance. Regular inspections, fluid analysis, and adherence to manufacturer guidelines can significantly extend the lifespan of hydraulic power packs and reduce downtime.

Tips: Implement a proactive maintenance schedule that includes regular fluid checks, filter replacements, and seal integrity assessments. Utilizing technology like predictive maintenance tools can also help in identifying potential failures before they lead to costly repairs.

Additionally, keeping accurate records of maintenance activities can aid in monitoring trends over time. A study by the Fluid Power Journal highlights that organizations that track maintenance actions see a 20-25% reduction in unexpected hydraulic failures. Ensuring that personnel is trained on the specific maintenance requirements of hydraulic systems can further enhance system performance and reliability.

The Importance of Regular Maintenance for Hydraulic Power Packs

Choosing the Right Hydraulic Power Pack for Your Industrial Needs

When selecting the right hydraulic power pack for industrial applications, it is crucial to consider several factors that determine efficiency and performance. According to a report by the International Hydraulics Association, approximately 60% of industrial machinery encounters operational inefficiencies due to improperly sized hydraulic systems. Therefore, accurately calculating the required flow rate and pressure can significantly enhance operational effectiveness. It is recommended to analyze the specific demands of your application, including load requirements and duty cycle, to ensure the hydraulic power pack meets the necessary specifications.

Moreover, the choice of power pack configuration—be it single-phase or three-phase power—plays a vital role in operational costs and reliability. In a recent industry analysis, around 70% of businesses reported reduced energy consumption and downtime by opting for three-phase hydraulic systems, which provide higher efficiency for heavy-duty applications. Additionally, factors such as tank size and fluid type should not be overlooked, as they influence the longevity and performance of the hydraulic system. By committing to these essential considerations, industrial operators can achieve optimal results from their hydraulic power packs.

Related Posts

-

Exploring the Benefits of Yuken Directional Valves for Enhanced Hydraulic Performance

-

Exploring the Benefits of Advanced Hydraulic Directional Valves for Efficient Fluid Control

-

Understanding the Role of Hydraulic Valves in Modern Industrial Applications

-

Unlocking Efficiency: The Vital Role of Hydraulic Pressure Relief Valves in Industrial Systems

-

Maximizing Efficiency: How Directional Control Valves Transform Hydraulic Systems