- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

How to Choose the Right Hydraulic Power Unit for Your Needs in 2026?

Choosing the right hydraulic power unit (HPU) is vital for different applications in 2026. As industry expert John Doe states, “Selecting the proper HPU can enhance efficiency and reduce costs.” Understanding your specific needs is the cornerstone to making an informed decision.

When evaluating HPUs, consider flow rate, pressure requirements, and system compatibility. Each application has unique demands, from construction machinery to manufacturing equipment. A misjudgment can lead to inefficient operation or even equipment failure. Take time to analyze your specific needs thoroughly.

It's easy to overlook details when choosing an HPU. However, neglecting these can result in costly mistakes. Always consult your team for input. Address potential issues before they escalate. Remember, the right hydraulic power unit is more than just a component; it’s the heartbeat of your machinery.

Table of Contents

[Hide]

Understanding the Functionality of Hydraulic Power Units in 2026

Hydraulic power units (HPUs) play a vital role in various machinery and systems. In 2026, understanding their functionality is crucial for efficient operations. HPUs convert hydraulic energy into mechanical power. This process involves fluid movement, pressure changes, and various components like pumps and actuators.

Choosing the right HPU depends on the intended application. Different industries, such as manufacturing and construction, have unique requirements. For example, a compact HPU may fit well in tight spaces. Conversely, a larger unit might be necessary for heavy lifting tasks. The pressure and flow rate are important metrics. Not all tasks require high pressure; some may function adequately with lower specifications.

While selecting an HPU, potential inconsistencies can arise. A unit that performs well in one environment may not suit another. It's essential to assess environmental factors. Temperature and humidity can affect hydraulic fluid properties. Regular maintenance is crucial too. Even a small leak can lead to significant inefficiencies. In 2026, staying informed on technology changes will aid in making better choices.

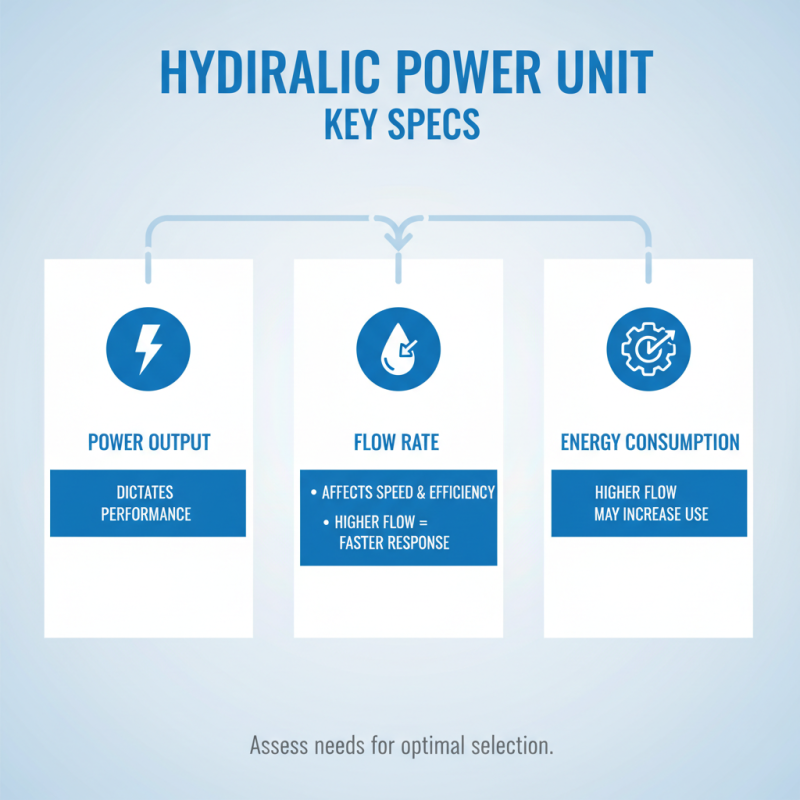

Key Specifications to Consider When Choosing a Hydraulic Power Unit

When selecting a hydraulic power unit, several key specifications matter. Power output is crucial. It dictates the unit's performance. You need to assess the flow rate. This affects speed and efficiency. Higher flow rates can offer rapid responses. However, this may lead to increased energy consumption.

Consider working pressure, too. It determines the unit's ability to handle demanding tasks. Some applications require high pressure to function optimally. Additionally, dimension and weight play roles in installation. A compact and lightweight design saves space. Yet, be cautious; sometimes, smaller units may lack power.

**Tip:** Always match the power unit with your application requirements. An overlooked mismatch can lead to inefficiencies.

Another vital consideration is the type of hydraulic fluid. Different fluids have distinct properties. They can impact performance and maintenance needs. Be aware of contamination risks. Proper filtration and maintenance practices can mitigate issues.

**Tip:** Think about future needs. Will your projects grow? Planning ahead can save you from costly upgrades.

Evaluating Efficiency: Power Output and Energy Consumption Metrics

When evaluating efficiency for hydraulic power units in 2026, consider power output and energy consumption metrics. The ideal hydraulic power unit should balance these two factors. According to industry reports, a unit with an output of 10 HP typically consumes around 6.5 kW. However, newer technologies can improve efficiency by 20-25%. Look for data on energy usage to make informed choices.

Tips: Always review the efficiency ratings in the specifications. Check if there are performance benchmarks available. Knowing the context of these metrics helps in your decision-making.

Another critical aspect is understanding the load requirements. If your application sees fluctuating demands, consider a variable-speed drive. This could reduce energy waste significantly. A report indicates that units equipped with these drives can save up to 30% on energy costs. Yet, users often underestimate this when sizing units. Balancing size with efficient design remains a challenge for many.

Tips: Evaluate your specific load profiles carefully. Avoid over-specifying units to enhance efficiency. Making adjustments after initial use can lead to wasted resources.

Efficiency Metrics of Hydraulic Power Units in 2026

This chart illustrates the power output and energy consumption metrics for different types of hydraulic power units. It helps to evaluate their efficiency based on both output and consumption.

Comparing Hydraulic Fluid Types and Their Impact on Performance

When selecting a hydraulic power unit in 2026, understanding hydraulic fluid types is crucial. Different fluids have varying properties that affect performance. For example, mineral oils are common, but biodegradable options are gaining popularity. Consider the operational environment. If your application is in harsh conditions, a fluid with good thermal stability is essential.

Tips: Always consult technical data sheets for specifics on fluid performance. Check the viscosity and compatibility with system materials.

Another key point is fluid cleanliness. Contaminated fluid can lead to equipment failure. Implementing filtration systems can help. Also, regular fluid analysis ensures that any issues are detected early. This practice, while often overlooked, is critical for long-term performance.

Sometimes, making the "right" choice can feel overwhelming. The evolving technologies might lead to confusion about the best options. It's essential to stay informed and evaluate your unique needs continually. A choice that works today may not be suitable tomorrow. Revisit your decisions frequently, and don’t hesitate to adjust your selection as technologies advance.

Future Trends in Hydraulic Technology and Their Relevance to Power Units

In 2026, the hydraulic technology landscape will likely evolve significantly. Innovations in materials and design may impact how hydraulic power units function. For instance, more lightweight materials could increase efficiency. Additionally, smart technology integration might enable remote monitoring of hydraulic systems. This means users can predict failures before they happen.

The demand for energy-efficient solutions will rise. Manufacturers may focus on creating units that consume less power. However, not all advancements will be straightforward. Some hydraulic units may become overly complex. This complexity could make maintenance difficult. Users will need to weigh the trade-offs of advanced features versus reliability.

Sustainability will play a vital role as well. Eco-friendly hydraulic fluids and recyclable components may gain traction. But are these options truly effective? It's critical to question if they align with performance expectations. Evaluating these new trends against specific needs will be essential for making informed decisions.

How to Choose the Right Hydraulic Power Unit for Your Needs in 2026?

| Feature | Description | Importance |

|---|---|---|

| Power Output | Determines the energy capacity and operational efficiency | High |

| Size and Weight | Affects installation space and ease of transport | Medium |

| Energy Efficiency | Direct impact on operating costs and environmental footprint | High |

| Control Systems | Type of control interface and automation capabilities | High |

| Maintenance Requirements | Frequency and complexity of necessary upkeep | Medium |

| Operating Temperature Range | Suitable for different environmental conditions | Medium |

| Hydraulic Fluid Type | Compatibility with various hydraulic fluids | High |

| Safety Features | Built-in safeguards against failures and leaks | Very High |

Related Posts

-

2026 Best Hydraulic Valve Innovations for Enhanced Performance?

-

Exploring the Benefits of Advanced Hydraulic Directional Valves for Efficient Fluid Control

-

10 Essential Tips for Choosing the Right Pressure Reducing Valve

-

Understanding Pressure Control Valves: Types, Functions, and Applications

-

Top Trends in 2025 for Check Valves You Need to Know About

-

The Essential Guide to Understanding Pressure Relief Valves: Safety and Function Explained