- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

How to Choose the Right Hydraulic Power Unit for Your Needs?

Choosing the right hydraulic power unit is crucial for various applications. These units provide the necessary power for machines and tools. With many options available, making an informed decision can be daunting.

The selection process should consider specific needs. Factors like load capacity, pressure requirements, and environment matter. Not all hydraulic power units are created equal. Some may not perform well in certain conditions, and that can lead to frustration.

Keep in mind that some units may not suit your application. It is important to evaluate your requirements carefully. Seek advice if necessary, and don't rush. An informed choice will lead to better efficiency and cost savings.

Table of Contents

[Hide]

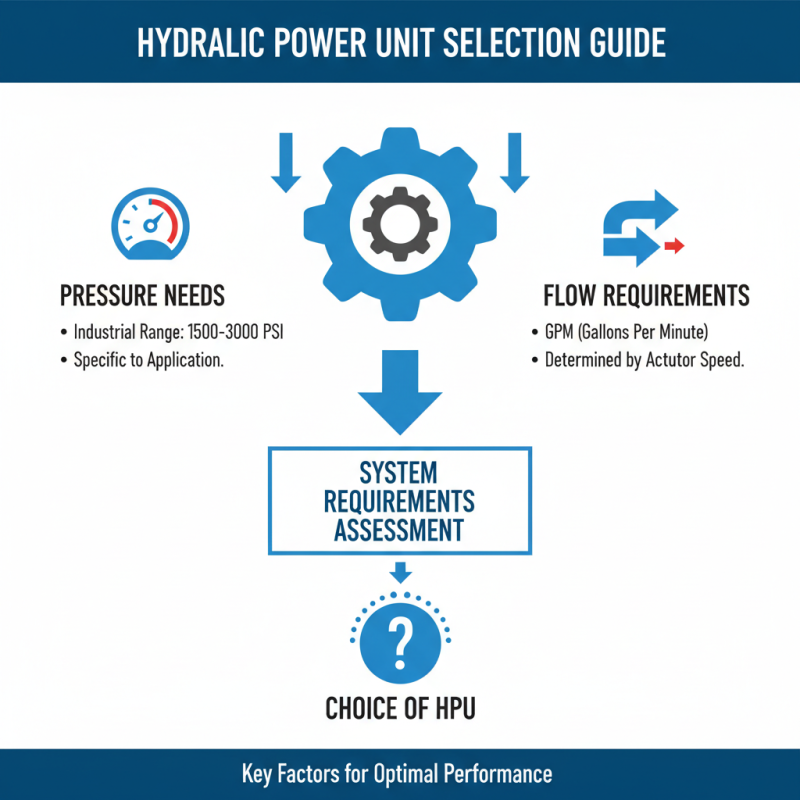

Identifying Your Hydraulic System Requirements

When selecting a hydraulic power unit, identifying your system requirements is crucial. Assess the application’s pressure and flow needs. Typically, a system requires a specific pressure range, often between 1500 to 3000 PSI for industrial applications. Understanding these parameters will steer your decision-making process.

Consider the environment where the unit will operate. Will it be in a dusty area or exposed to extreme temperatures? These factors can influence the type of hydraulic unit you need. For instance, moisture resistance becomes vital in outdoor applications. According to industry data, around 20% of hydraulic failures can be traced to improper environmental conditions.

**Tip:** Always calculate the peak demand for flow. This prevents under-sizing the unit, which can lead to inefficiencies. Over-sizing can waste energy and increase costs. It's a fine balance, and gathering data from your existing systems can help clarify this.

Additionally, assess serviceability. Components that are difficult to access can complicate repairs, leading to downtime. A simpler design can often lead to lower long-term costs and better reliability. Regular maintenance checks enhance performance, contributing to the longevity of the hydraulic unit.

Understanding Different Types of Hydraulic Power Units

Hydraulic Power Units (HPUs) come in various types. Understanding these types is crucial for effective application. Fixed displacement pumps are common in many systems. They offer consistent flow and pressure, but may lack flexibility. This makes them suitable for simple tasks. Adjustability is limited. If needs change, these units may fall short.

Variable displacement pumps provide an interesting alternative. They adapt flow rates based on demand. This can lead to increased efficiency. However, they are often more complex. Maintenance might be trickier. Users must balance power needs with operational simplicity. Unanticipated downtime can arise from improper choices.

Another option is electric hydraulic power units. They are popular in compact applications. These units can integrate well into automated systems. Yet, they might not deliver the high power needed for larger machinery. Users should assess overall system requirements carefully. A mismatch can lead to underperformance. Investing time in comparison will yield better results.

How to Choose the Right Hydraulic Power Unit for Your Needs? - Understanding Different Types of Hydraulic Power Units

| Type of Hydraulic Power Unit | Common Applications | Power Range (HP) | Key Features | Pros | Cons |

|---|---|---|---|---|---|

| Electric Hydraulic Power Unit | Manufacturing, Metalworking | 1-30 HP | Energy efficient, low noise, easy to control | Quiet operation, reliable performance | Dependent on electrical supply, limited mobility |

| Gasoline Hydraulic Power Unit | Construction, Landscaping | 5-50 HP | Portable, high power output | High mobility, versatile use | Noisy, requires regular maintenance |

| Diesel Hydraulic Power Unit | Mining, Heavy Duty Machinery | 10-100 HP | Durable, high torque | Powerful for heavy applications | Environmental regulations, fuel needs |

| Hybrid Hydraulic Power Unit | Agricultural equipment, Robotics | 3-25 HP | Combines electric and hydraulic power | Energy efficient, lower emissions | More complex systems, higher initial cost |

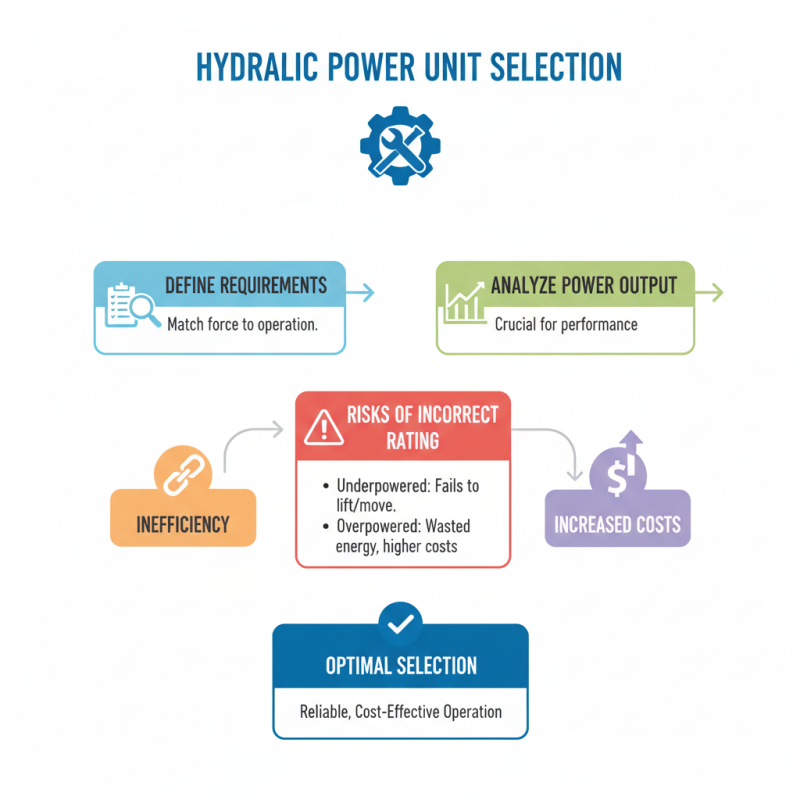

Evaluating Power Output and Specifications

When selecting a hydraulic power unit, analyzing power output is crucial. You should start by understanding your specific requirements. Each operation demands different force levels. An incorrect power rating can lead to inefficiencies. It may not lift or move loads as needed. Sometimes, more power results in wasted energy and increased costs.

Specifications are just as important. Consider the hydraulic unit's flow rate. A unit that supplies too much or too little fluid can cause issues. For example, too high a flow rate may lead to overheating. This can damage the system and shorten its lifespan. Furthermore, check the operational pressure required for your tasks. Each project might demand different limits.

Evaluate both portability and size. A compact unit might be easier to transport but may lack sufficient power. Conversely, larger units might not fit in tight workspaces. Users often overlook these factors during selection. They end up with cumbersome equipment that limits their tasks. Finding the right balance in size and power output is key to efficiency and productivity.

Considering Energy Efficiency and Environmental Impact

When selecting a hydraulic power unit (HPU), energy efficiency is a key factor. High energy consumption leads to increased operational costs. According to a report by the Energy Efficiency Institute, hydraulic systems can consume up to 30% more energy than necessary if not properly designed. This inefficiency results in unnecessary energy wasted.

Environmental impact cannot be overlooked. Hydraulic fluids can pollute water sources if leaks occur. The Environmental Protection Agency (EPA) indicates that significant spills can release thousands of gallons of hydraulic fluid, harming ecosystems. Therefore, choosing an HPU that uses biodegradable fluids can make a positive difference. It may decrease environmental risks while boosting your company’s sustainability image.

It is essential to consider the whole lifecycle of the HPU. Sometimes, more energy-efficient models come with higher initial costs. This can discourage investment despite long-term savings. Reflecting on these trade-offs is necessary. Energy efficiency does not always correlate directly with lower emissions. Understanding these nuances can guide users to make smarter choices for their operations.

Energy Efficiency Ratings of Hydraulic Power Units

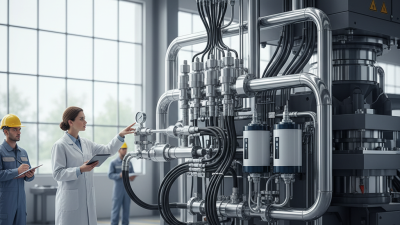

Assessing Compatibility with Existing Equipment

When selecting a hydraulic power unit (HPU), compatibility with existing equipment is crucial. This step can save time and reduce costs. Start by analyzing current hydraulic systems in use. Note any specific requirements, like flow rates and pressure ratings. Mismatched components can cause inefficiencies or failures, impacting productivity.

Consider the size and layout of your working space. Matching the dimensions of the HPU to your setup is essential. A unit that doesn't fit well may require additional modifications, leading to unexpected expenses. Don't forget about power source compatibility — the wrong voltage or phase can halt operations.

Listen to feedback from team members who work with hydraulic systems. They may provide insights into potential pitfalls. Their experience can highlight issues you might overlook. Additionally, gather information on the hydraulic fluids currently in use. Ensuring that the HPU can operate effectively with them is vital. All these factors play a role in choosing the right unit for your needs.

Related Posts

-

How to Choose the Right Hydraulic Power Unit for Your Needs in 2026?

-

Best Hydraulic Power Unit for Your Needs in 2023

-

10 Essential Tips for Maintaining an Efficient Hydraulic System

-

10 Essential Tips for Choosing the Right Pressure Reducing Valve

-

Understanding the Role of Check Valves in Modern Industrial Systems

-

Understanding the Role of Hydraulic Valves in Modern Industrial Applications