- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

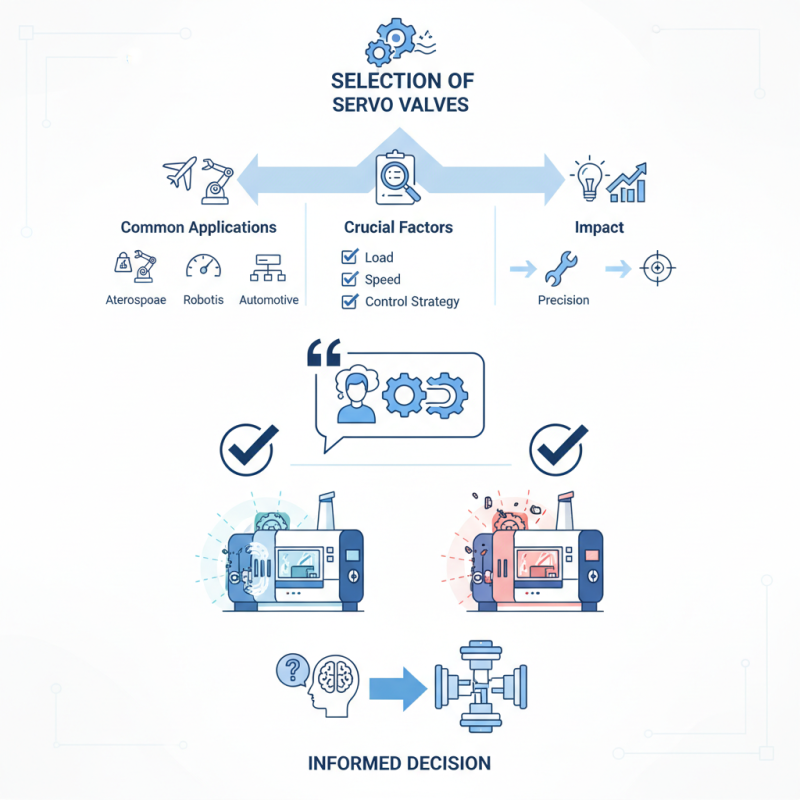

How to Choose the Right Servo Valves for Your Applications?

Choosing the right servo valves for your applications can be a daunting task. With various options and specifications, understanding your needs is crucial. As John Smith, an expert in hydraulic systems, once stated, "The right servo valve can enhance performance significantly." This emphasizes the importance of making informed decisions.

Servo valves control fluid power in hydraulic systems. They regulate flow and pressure, affecting machine performance directly. Selecting the appropriate valve impacts efficiency and precision. Common applications include aerospace, robotics, and automotive sectors. Each application has unique requirements that dictate the choice of servo valves.

Careful assessment of factors like load, speed, and control strategy is paramount. Sometimes, users overlook these details. This can lead to underperformance or even system failures. Understanding your specific needs allows you to identify the perfect servo valve for your solution. The difference between good and excellent operation often lies in this selection process.

Table of Contents

[Hide]

Understanding Servo Valves: Types and Key Features

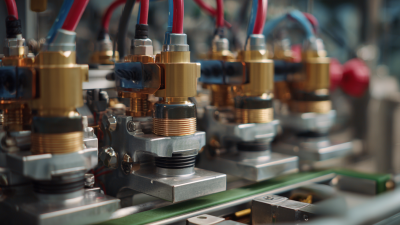

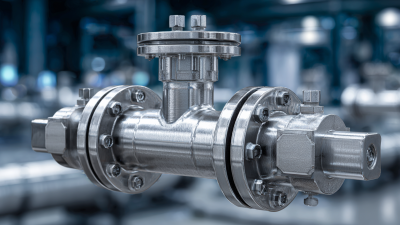

Servo valves are essential components in fluid power systems. Understanding their types and key features is crucial for selecting the right one for your applications. There are several types of servo valves, including proportional and direct-acting valves, each serving different purposes.

Proportional valves adjust fluid flow based on the input signal. Direct-acting valves operate with high precision and are often used in control applications. It's vital to consider flow rate, pressure range, and response time when selecting a servo valve. A report by the Fluid Power Journal indicated that improperly chosen valves could lead to a 20% efficiency loss in hydraulic systems.

Tip: Always align the valve selection with system specifications. Consider compatibility with the fluid type and temperature, as mismatch can lead to premature wear.

Another key feature is the control method. Some valves use electronic control, while others use mechanical systems. Electronic control offers faster response times. However, it can introduce complexity that may not be necessary for simpler applications. Always evaluate the application's demands carefully.

Tip: Simplicity often leads to reliability. If the application doesn’t require advanced features, consider opting for a basic model.

Servo Valves Selection Criteria

This chart illustrates the importance levels of different selection criteria when choosing servo valves for various applications. Criteria such as flow rate and response time are essential for optimal performance, while pressure and temperature ranges also play significant roles.

Criteria for Selecting Servo Valves Based on Application Requirements

Choosing the right servo valves for specific applications can be challenging. It's crucial to identify the application requirements first. Consider the type of fluid and the operating pressure. These factors dictate valve compatibility. Also, think about flow rates. High precision needs more specific flow control. Some applications may not require that level of accuracy.

Next, assess the environment where the valve will operate. High temperatures or corrosive substances can affect performance. Selecting materials that withstand these conditions is vital. Think about energy efficiency as well. Some valves consume more energy than others. This can impact operational costs over time.

Failure to consider these criteria can lead to issues. For example, a valve chosen for its size may not perform well under pressure. If the environment is too harsh, the valve may fail. It's important to reflect on these factors before making a decision. Evaluate all aspects thoroughly to avoid unnecessary problems.

Evaluating Flow Rates: Impact on Performance and Efficiency

Choosing the right servo valve involves understanding flow rates. Flow rate impacts both performance and efficiency in hydraulic systems. A study found that improper flow rate can reduce efficiency by up to 25%. This inefficiency can lead to overheating and wear, which shortens equipment lifespan.

When evaluating flow rates, consider the application. For example, in aerospace systems, precise control is crucial. A minor fluctuation in flow can affect aircraft performance. Industry guidelines suggest maintaining a flow rate within ±5% of the required value for optimal performance.

Additionally, the materials of the servo valve impact flow rate. Certain materials can cause increased friction, which alters flow dynamics. Reports indicate that using high-quality materials can enhance flow efficiency by about 15%. Addressing these factors can help in selecting the appropriate servo valve for your unique needs.

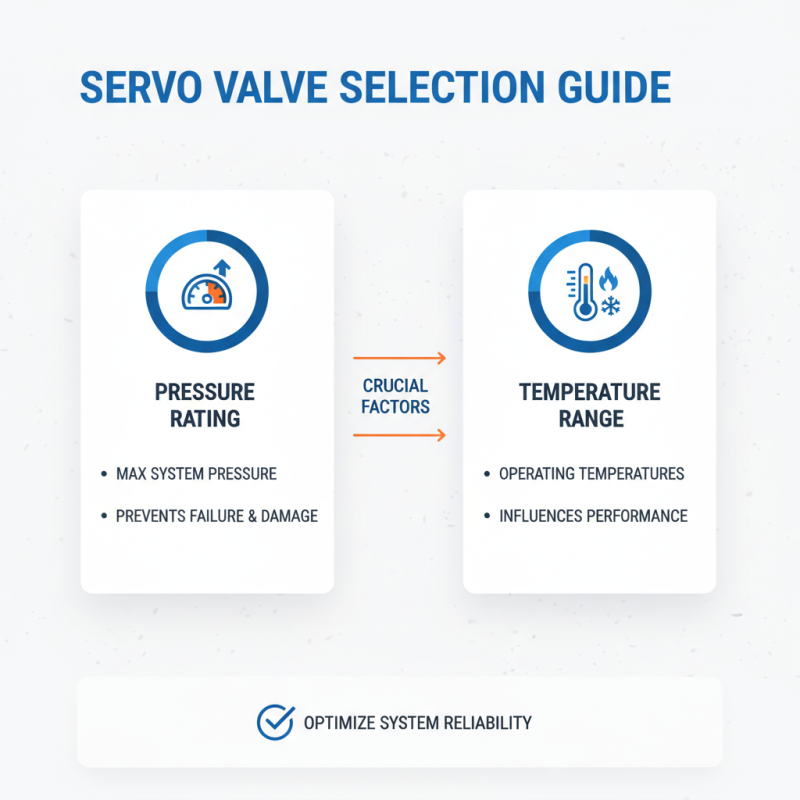

Considering Pressure Ratings and Temperature Ranges in Selection

When selecting servo valves for your applications, it’s crucial to consider pressure ratings and temperature ranges. These factors significantly influence valve performance. Understanding the maximum pressure your system will encounter helps ensure safe operation. Valves that cannot handle high pressures may fail, leading to system damage.

Temperature is another critical aspect. Servo valves must operate efficiently within specific temperature ranges. High temperatures can alter fluid properties, affecting valve responsiveness. Conversely, low temperatures can lead to increased viscosity. Evaluate the environment where the valves will be used. Certain applications may expose them to extreme conditions.

**Tips:** Always refer to manufacturer specifications for pressure and temperature. Verify compatibility with the fluids in your system. Consider the potential for temperature variations that could affect performance. Researching different materials can also help in preventing premature wear. Establishing a solid understanding of these parameters can prevent costly mistakes.

Assessing Control Precision: Importance for System Integration

Assessing control precision is essential when selecting servo valves for various applications. Precision affects the performance and efficiency of the entire system. According to industry reports, systems with high control precision can increase productivity by up to 25%. This improvement is critical in sectors like aerospace and manufacturing.

Control precision directly impacts response times and stability. Systems that lack precision can lead to fluctuations, which results in inefficiencies. Data shows that a 1% error in control can cause a 10% drop in system output. Engineers must weigh the trade-offs between cost and the level of precision required. This decision is not always straightforward.

It is crucial to test the servo valves in real-life scenarios. Simulation data may not reveal all potential issues. Some applications require adjustments during integration. Engineers must prepare for these challenges. Continuous evaluation and feedback loops can help refine control strategies. This iterative process ensures better alignment with operational goals.

Related Posts

-

The Future of Automation: How Servo Valves are Revolutionizing Industry Efficiency

-

How to Choose the Right Hydraulic Unit for Your Industrial Needs

-

Understanding the Role of Check Valves in Modern Industrial Systems

-

Top 10 Benefits of Pilot Operated Check Valves in Industrial Applications

-

How to Choose the Right Directional Control Valve for Your Project

-

Exploring the Benefits of Yuken Directional Valves for Enhanced Hydraulic Performance