- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

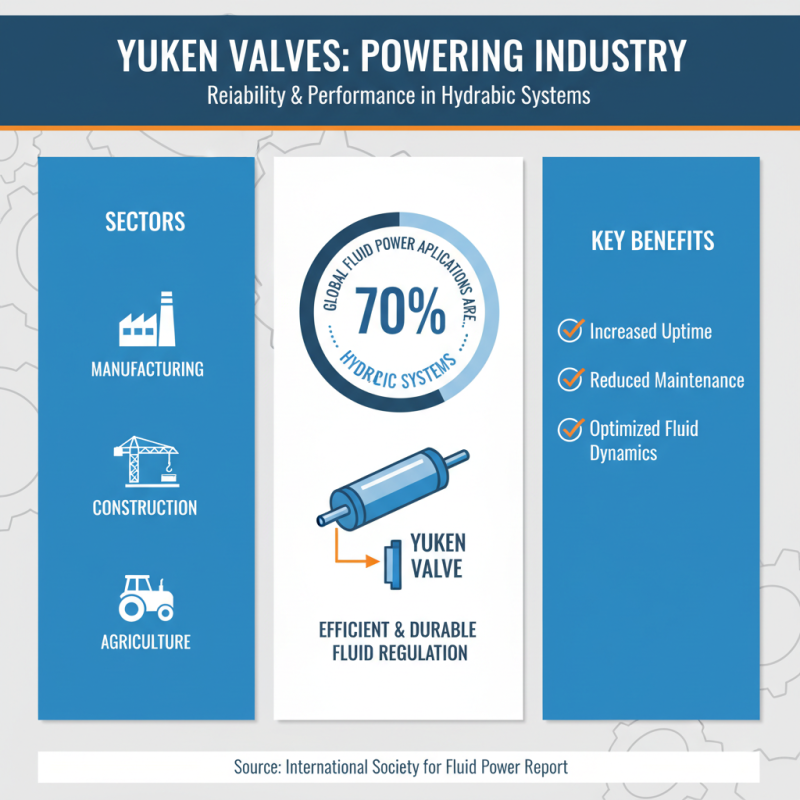

Why Choose Yuken Valves for Your Industrial Applications

In the competitive landscape of industrial applications, selecting the right components can significantly impact operational efficiency and cost-effectiveness. As industries strive for higher productivity and minimized downtime, the demand for reliable and high-performance hydraulic solutions continues to rise. According to a report by Allied Market Research, the global hydraulic valve market is projected to reach $17.2 billion by 2027, driven by the increasing adoption of automated systems in manufacturing and construction sectors.

Yuken valves stand out as a premier choice for these applications, owing to their proven reliability and advanced technology. With their ability to deliver precise control and enhanced performance in hydraulic systems, Yuken valves contribute to optimized energy consumption and reduced operational costs. Furthermore, industry studies indicate that employing high-quality hydraulic components can lead to a 15% increase in efficiency, underscoring the importance of selecting the right valve for industrial applications.

As businesses look to the future, investing in Yuken valves not only addresses immediate operational needs but also aligns with long-term sustainability goals. In an era where efficiency and resource management are paramount, choosing Yuken valves positions organizations to meet both current demands and future challenges effectively.

Table of Contents

[Hide]

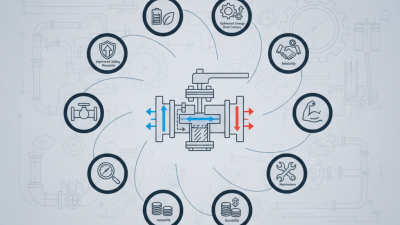

Benefits of Using Yuken Valves in Industrial Settings

When it comes to industrial applications, selecting the right hydraulic valves is crucial for optimal performance and efficiency. One of the key benefits of using high-quality valves is their ability to enhance operational reliability. These valves are designed to withstand harsh environments, ensuring consistent performance even under extreme conditions. This robustness translates to reduced downtime and lower maintenance costs, allowing businesses to maintain productivity levels without disruption.

Additionally, advanced hydraulic valves contribute significantly to energy efficiency in industrial settings. By providing precise control over fluid flow and pressure, they minimize energy wastage that often occurs with less efficient systems. This not only helps in cutting operational costs but also supports efforts toward sustainability by reducing the carbon footprint of industrial operations. Ultimately, utilizing top-tier hydraulic valves can lead to significant long-term savings and improved operational efficiency, making them an essential component in various industrial applications.

Benefits of Using Yuken Valves in Industrial Settings

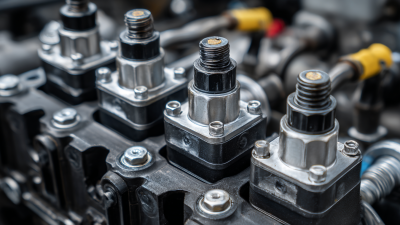

Key Features of Yuken Valves for Enhanced Performance

When it comes to industrial applications, the choice of valves can significantly impact performance and efficiency. Yuken valves stand out due to their impressive range of key features designed for enhanced performance. One notable attribute is their high reliability, which ensures that operations run smoothly with minimal downtime. These valves are engineered to handle various pressures and flow rates, making them versatile choices for different applications.

In addition to reliability, Yuken valves offer exceptional precision in control. This precision is vital for applications requiring exact flow regulation, allowing for improved process efficiency and product quality. Moreover, the integration of advanced technologies in the design of these valves contributes to energy savings, ultimately reducing operational costs over time.

**Tip:** When selecting valves for your application, consider the specific operational conditions and requirements. Proper sizing and material selection can greatly enhance performance and longevity.

Another feature worth mentioning is the ease of maintenance associated with Yuken valves. Their design facilitates straightforward servicing, which minimizes time and effort spent on upkeep. Regular maintenance not only prolongs equipment life but also ensures peak performance during operation.

**Tip:** Establish a regular inspection schedule for your valves to identify any wear or performance issues early. This proactive approach can help maintain efficiency and prevent costly breakdowns.

Why Choose Yuken Valves for Your Industrial Applications - Key Features of Yuken Valves for Enhanced Performance

| Feature | Description | Benefits |

|---|---|---|

| High Pressure Rating | Designed to handle pressures up to 350 bar. | Enhances durability and reliability in demanding conditions. |

| Compact Design | Space-efficient design allows for easy installation. | Saves valuable space in industrial setups. |

| Wide Temperature Range | Operable in temperatures from -30°C to +80°C. | Versatile usage across various environments. |

| Low Noise Operation | Engineered for quiet function. | Reduces noise pollution in industrial spaces. |

| Customizable Options | Available in multiple flow configurations. | Allows for tailored solutions to meet specific application needs. |

Applications of Yuken Valves Across Various Industries

Yuken valves are becoming increasingly popular in a variety of industrial applications due to their reliability and performance. Commonly utilized in sectors such as manufacturing, construction, and agriculture, Yuken valves effectively regulate fluid dynamics in hydraulic systems. According to a report by the International Society for Fluid Power, hydraulic systems account for over 70% of all fluid power applications across various industries. This prevalence underscores the need for efficient and durable components like Yuken valves.

In manufacturing, Yuken valves enhance the precision of automated machinery, optimizing processes and reducing waste. For instance, in assembly lines where hydraulic presses are employed, Yuken valves ensure consistent pressure application, which is critical for maintaining product quality. In agriculture, these valves are vital for controlling hydraulic systems in tractors and other machinery, allowing for improved efficiency and productivity, thereby increasing crop yields. Reports indicate that agricultural machinery fitted with advanced hydraulic components can increase operation efficiency by up to 30%.

Tips: When selecting valves for your industrial applications, consider the specific requirements of your system, including pressure ratings and flow capacity. It's also beneficial to consult industry standards, such as those from the Hydraulic Institute, to ensure compatibility and optimal performance. Regular maintenance and monitoring of valve performance can further enhance their lifespan and efficiency in your operations.

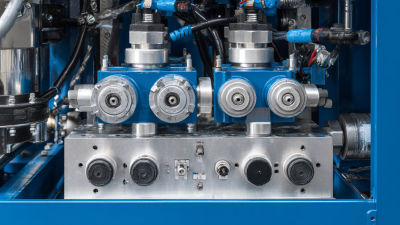

Comparative Analysis: Yuken Valves vs. Competitors

When evaluating hydraulic valves for industrial applications, the decision often boils down to performance, reliability, and cost-effectiveness. Yuken valves are frequently recognized for their superior engineering and efficiency, but how do they stack up against leading competitors in the market? A comparative analysis reveals that Yuken valves often outperform in terms of energy consumption and lifecycle costs. According to a recent industry report from TECHnalysis, Yuken valves are designed to reduce operational costs by approximately 15-20% compared to other top brands due to their advanced hydraulic technology.

Moreover, reliability plays a crucial role in industrial applications. Studies indicate that Yuken valves have a failure rate significantly lower than that of competitive brands. The Machinery Safety Institute reported that Yuken valves achieved a reliability rating of 98.5%, in contrast to the 94.2%% average reliability of competing products. This difference can lead to substantial maintenance savings and uninterrupted operations in a demanding industrial environment. Consequently, the commitment to quality and performance by Yuken stands out, making a compelling case for their use in various applications, from automotive to manufacturing sectors.

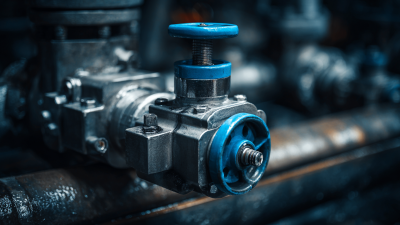

Maintenance and Support for Yuken Valves in Industrial Operations

When it comes to industrial operations, the maintenance and support of hydraulic valves are crucial for ensuring optimal performance and minimizing downtime. Regular maintenance of these components is vital to identify wear and tear, prevent sudden failures, and extend the equipment's lifespan. Scheduled inspections and timely servicing can help in promptly addressing issues before they escalate, thus maintaining the operational efficiency of the machinery.

Furthermore, having a reliable support system in place enhances the overall productivity of industrial processes. Access to knowledgeable technicians and comprehensive resources allows operators to troubleshoot problems quickly and effectively. This support not only aids in resolving immediate concerns but also provides valuable insights into best practices for usage and care. By fostering a proactive approach to maintenance and ensuring that expert help is readily available, industries can enhance their operational reliability and reduce the long-term costs associated with equipment failure.

Related Posts

-

Exploring the Benefits of Yuken Directional Valves for Enhanced Hydraulic Performance

-

Understanding Yuken Directional Valves and Their Applications in Modern Hydraulic Systems

-

2025 How to Choose the Best Yuken Valve for Your Hydraulic System

-

The Essential Guide to Understanding Hydraulic Power Packs in Industrial Applications

-

Why Flow Control Valve is Essential for Effective System Performance

-

Top 10 Benefits of Pilot Operated Check Valves in Industrial Applications