- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

Best Hydraulic Valve Repair Techniques for Optimal Performance?

Hydraulic valve repair is critical for maintaining optimal performance in hydraulic systems. According to a report from the International Fluid Power Society, over 40% of hydraulic system failures are linked to valve issues. Proper maintenance and repair techniques can significantly extend the life of hydraulic components.

Expert Mark Johnson, a renowned figure in the hydraulic industry, emphasizes, "Regular valve maintenance is crucial. Neglecting it can lead to significant downtime." His insights underscore the need for effective hydraulic valve repair strategies. Yet, many organizations overlook this aspect, often leading to costly repairs and operational inefficiencies.

Additionally, recent studies show that only 30% of companies implement best practices in hydraulic valve maintenance. This statistic highlights a critical area for improvement. There remains a gap between knowledge and execution in hydraulic valve repair. Many technicians still rely on outdated methods. Implementing modern techniques is vital for enhancing system reliability.

Table of Contents

[Hide]

Understanding Hydraulic Valves and Their Functions

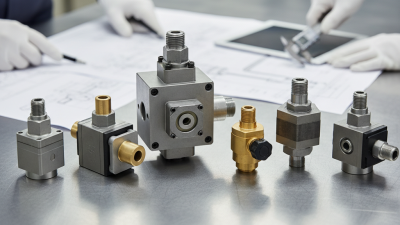

Hydraulic valves play a crucial role in fluid power systems. They control the flow and direction of hydraulic fluids. Understanding how these valves work is essential for optimal performance. Each valve has specific functions, such as regulating pressure and controlling speed. This makes them vital in many industrial applications.

Common types include directional, pressure, and flow control valves. Their design influences how effectively they perform tasks. For instance, a directional valve directs fluid to various actuators. A pressure valve prevents system overload. However, performing regular maintenance is easy to overlook. It requires attention to detail, which many often skip.

Leaks, sticking parts, and damaged seals can occur over time. Detecting these issues promptly is key. Inspecting hydraulic valves should be part of a routine check. Missing small signs may lead to larger problems. Delaying repairs impacts system efficiency significantly. Regularly reviewing valve performance ensures optimal function and longevity. A conscious effort to monitor can lead to better outcomes.

Best Hydraulic Valve Repair Techniques for Optimal Performance

| Repair Technique | Description | Optimal Applications | Expected Outcome |

|---|---|---|---|

| O-Ring Replacement | Replacing worn O-rings to prevent leaks and ensure proper sealing. | Used in leakage issues in both low and high-pressure systems. | Improved sealing and reduced leakage. |

| Valve Cleaning | Thorough cleaning of valve components to remove debris and contaminants. | Recommended for valves with reduced flow rates due to blockages. | Restoration of flow rates and smooth operation. |

| Seat Resurfacing | Refinishing valve seats to ensure a tight seal. | Applicable in cases of leakage or poor sealing. | Enhanced valve performance and sealing integrity. |

| Spring Replacement | Replacing weak or broken springs that impact valve operation. | Critical for valves requiring precise pressure regulation. | Consistent valve response and stability. |

| Seal Replacement | Replacing aging seals to enhance performance and prevent leaks. | Essential for all hydraulic systems with aging components. | Restored performance and reliability in operation. |

Common Issues in Hydraulic Valve Performance

Hydraulic valves play a crucial role in fluid control systems, but they often encounter several common issues. One major problem is leakage, which can stem from worn seals or improper installation. This type of failure might go unnoticed initially, leading to reduced efficiency over time. Regular inspection helps identify such issues early, saving both time and resources.

Another frequent challenge is valve sticking. This often occurs due to dirt or debris accumulation in the valve mechanism. In some cases, poor lubrication can also contribute to this issue. Operators might overlook such maintenance needs, assuming everything is functioning correctly. Ensuring a clean environment and scheduled maintenance can mitigate these risks significantly.

Additionally, pressure fluctuations can affect performance. These irregularities might be attributed to inadequate system design or faulty components. Often, users tend to ignore such symptoms until it’s too late. Awareness and proactive management of hydraulic systems are essential for ensuring smooth operation and extending the life of the equipment.

Step-by-Step Diagnosis of Hydraulic Valve Problems

Hydraulic valves play a critical role in the performance of hydraulic systems. Diagnosing issues with these valves is essential for ensuring system efficiency. A report by the Hydraulic Institute states that up to 25% of hydraulic failures stem from valve malfunctions. Identifying the root causes can save time and costs.

Begin diagnosis by visually inspecting for leaks or unusual wear. Check fluid contamination, as dirty fluid can lead to valve sticking. In fact, a study found that 40% of hydraulic issues were directly linked to contaminated fluid. It’s essential to replace fluid regularly and maintain a clean system environment. Listen for abnormal sounds, which can indicate internal wear or cavitation.

After preliminary checks, move to pressure testing. This process can reveal hidden problems. The industry standard suggests that maintaining optimal pressure levels can enhance valve lifespan by 15-20%. If pressure tests fail, further disassembly may be necessary. It can be a labor-intensive process, requiring patience and detail-oriented work. Many overlook this step, leading to ongoing malfunction.

Proper diagnosis not only prevents future issues but also optimizes overall system performance.

Effective Techniques for Hydraulic Valve Repair

Hydraulic valves play a crucial role in various industrial applications. Proper maintenance is vital for their longevity. Unfortunately, many overlook this aspect. Regular inspections can identify common issues like leaks or sluggish response. Repair techniques should be standard practice for operators.

One effective approach involves disassembling the valve. Inspect each component with care. Look for wear or damage on seals and o-rings. Cleaning the parts ensures optimal function. It should never be rushed. After thorough inspection, reassemble the valve with proper torque specifications. Ignoring this can lead to future failures.

Fluid quality is another critical factor. Contaminated fluid can damage hydraulic systems. Regularly check fluid levels and cleanliness. Replace filters as needed. Implementing these techniques will enhance system reliability. However, it's essential to know when to seek professional help. DIY repairs can save time but may lead to errors. Investing in expertise can prevent costly mistakes.

Best Hydraulic Valve Repair Techniques for Optimal Performance

This chart displays the effectiveness of various hydraulic valve repair techniques based on performance improvements observed in field tests.

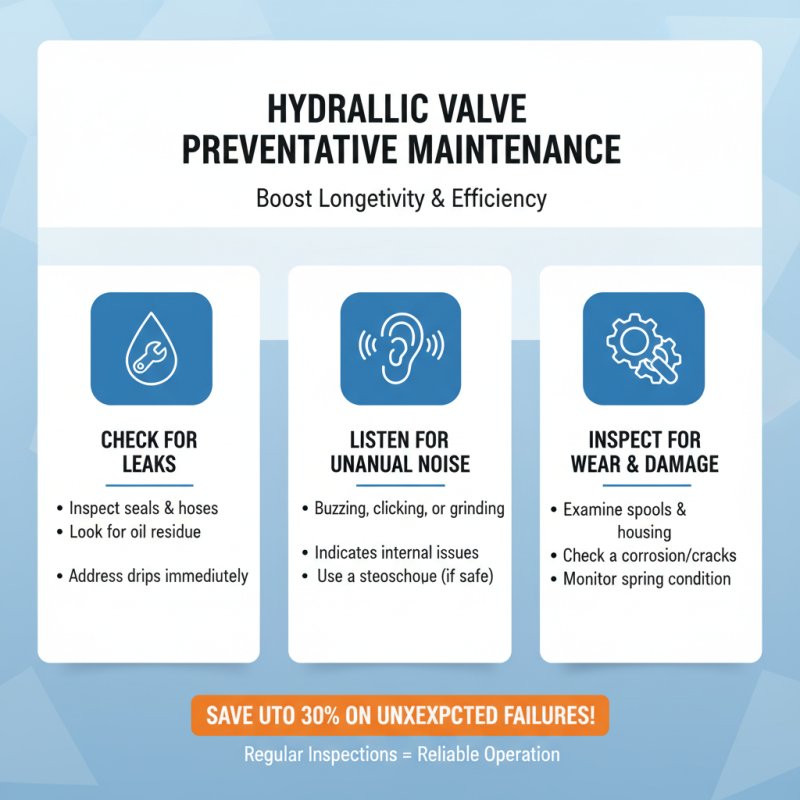

Preventive Maintenance Strategies for Hydraulic Valves

Preventive maintenance for hydraulic valves is crucial for their longevity and efficiency. According to industry reports, regular inspections can reduce unexpected failures by up to 30%. Operators should routinely check for leaks, listen for unusual noises, and inspect for wear. These early signs often indicate underlying issues that could escalate if ignored.

Adopting a scheduled maintenance plan helps maintain optimal performance. Maintaining fluid quality is essential. Contaminated fluid can cause damage to valve components. Reports suggest that about 70% of hydraulic system failures are related to fluid contamination. Utilizing proper filtration and replacement schedules can alleviate these risks.

Operators should also consider the environment where valves operate. Extreme temperatures and exposure to contaminants can affect their performance. Data indicates that valves in harsh conditions may require more frequent maintenance. Regular training for personnel on best practices can ensure awareness. Without proper training, teams may overlook critical checks. This gap can result in costly downtimes.

Related Posts

-

2025 How to Effectively Repair Hydraulic Valves for Optimal Performance

-

Understanding the Importance of Hydraulic Pressure Control Valves in Modern Industrial Applications

-

Understanding the Importance of Hydraulic Flow Control Valves in Modern Industrial Applications

-

7 Essential Tips for Choosing the Right Hydraulic Valve for Your Application

-

2026 Top Hydraulic Directional Valve Trends and Innovations?

-

2026 Best Hydraulic Valve Innovations for Enhanced Performance?