- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

2026 Best Hydraulic Valve Innovations for Enhanced Performance?

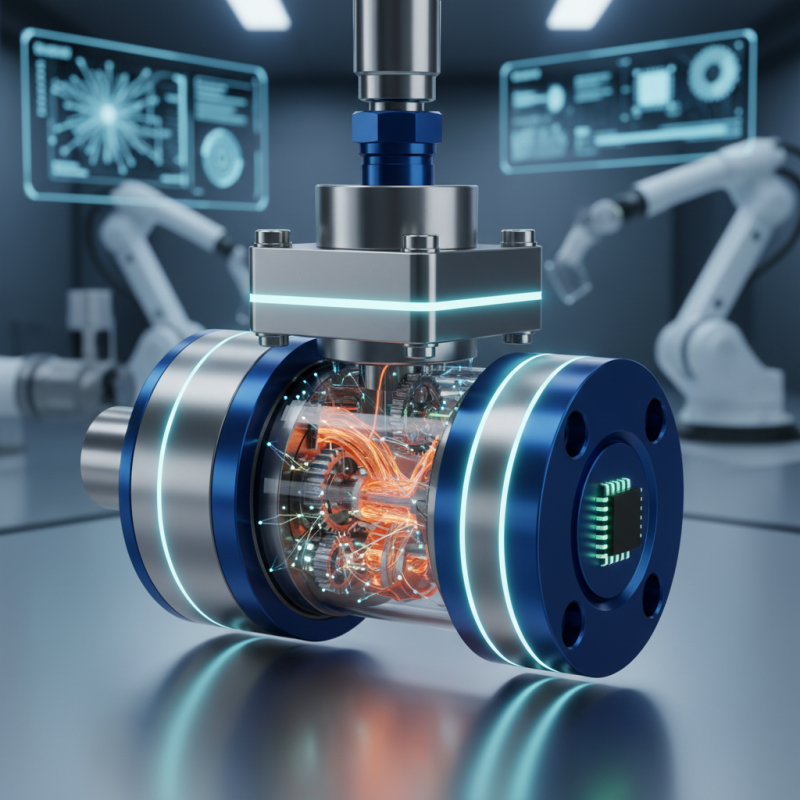

The hydraulic valve industry is witnessing remarkable innovations in 2026, focusing on enhancing performance and efficiency. According to a report by Research and Markets, the global hydraulic valve market is projected to reach $XX billion by 2025, with a CAGR of XX%. This growth is largely driven by advancements in technology, which allow for increased precision and reliability in hydraulic systems.

New designs in hydraulic valves are emerging, reflecting the ongoing demand for improved performance in various applications. For instance, smart hydraulic valves equipped with IoT technology can monitor and regulate fluid flow in real-time. Such innovations could lead to significant energy savings and reduced operational costs. However, challenges remain in integrating these complex systems seamlessly into existing frameworks.

Moreover, the reliability of hydraulic valves under extreme conditions still requires improvement. Instances of valve failure can lead to costly downtime. Addressing these concerns calls for a reevaluation of materials and manufacturing processes. The need for durability and efficiency in hydraulic valves emphasizes the importance of continuous innovation in this sector, driving the industry forward while highlighting areas for improvement.

Table of Contents

[Hide]

Advancements in Hydraulic Valve Design for 2026

In 2026, hydraulic valve design is undergoing significant changes. Recent industry reports reveal that innovative materials are improving durability and performance. Advanced polymers and composite materials are becoming more common. They reduce wear and increase resistance to extreme temperatures. This innovation leads to longer service life, cutting replacement costs.

Additionally, smart technology integration is reshaping valve functionality. Sensors within hydraulic valves can now monitor pressure and flow in real-time. This data-driven approach enhances operational efficiency by allowing for predictive maintenance. Yet, not every design accounts for the complexity of implementation. Users may face challenges adapting existing systems to these new technologies.

Manufacturers are also focusing on energy efficiency. Reports indicate that modern hydraulic valves can reduce energy consumption by up to 30%. However, not all designs achieve this target. Regular assessments and user feedback are essential to pinpoint areas for improvement. Adapting to this evolving landscape may prove challenging for some. Continuous adaptation is necessary to fully harness these advancements.

2026 Best Hydraulic Valve Innovations for Enhanced Performance

| Innovation | Feature | Benefits | Expected Impact |

|---|---|---|---|

| Smart Hydraulic Control | IoT integration for real-time monitoring | Improved efficiency and predictive maintenance | Reduced downtime and operational costs |

| Bio-Degradable Seals | Environmentally friendly materials | Reduced environmental impact and waste management | Sustainability in hydraulic systems |

| Enhanced Flow Control Valves | Advanced flow modulation technologies | Precision control and increased throughput | Higher system performance and responsiveness |

| Self-Repairing Materials | Materials that can autonomously seal leaks | Increased reliability and longevity | Cost savings on repairs and replacements |

| Wireless Control Systems | Remote operation capabilities | Increased flexibility and operator safety | Broader applications in hazardous environments |

Key Features of Next-Generation Hydraulic Valves

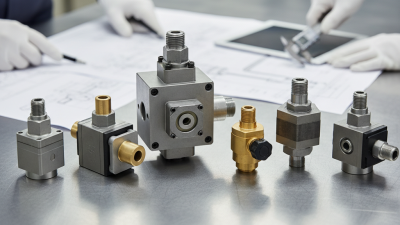

The next generation of hydraulic valves is transforming industry standards. Innovative designs focus on efficiency and reliability. Enhanced performance is at the forefront. These valves aim to meet rising operational demands. Users seek durability and responsiveness in hydraulic systems.

Key features include improved flow control. Advanced materials reduce wear and tear over time. These innovations promise quieter operation and lower energy consumption. However, the technology isn't foolproof. Some users report difficulties in initial calibration. Maintenance may require specialized training.

Adaptive controls are another essential feature. They allow for real-time adjustments based on system needs. This capability can lead to significant efficiency gains. Yet, there can be a learning curve. Engineers must adapt to new interfaces and functions. Balancing innovation with usability is vital for future success.

Innovative Materials and Technologies in Hydraulic Valves

Hydraulic valves play a crucial role in various industries. Their efficiency relies heavily on innovative materials and technologies. Recent advancements focus on reducing friction and enhancing durability. Composite materials are now making a mark. These lightweight options often outperform traditional metals. They resist corrosion and wear, extending valve life.

Moreover, the use of smart technologies is on the rise. Sensors can monitor pressure and flow in real-time. This data allows for better control and optimization. However, integrating these systems often presents challenges. Compatibility with existing components can be problematic. Industry players must address these issues to harness full benefits.

3D printing is another game-changer. It allows for customized designs that traditional methods cannot achieve. This innovation promotes rapid prototyping, but quality control is still a concern. Early adopters have reported inconsistencies in material properties. Continuous refinement is necessary for widespread acceptance. A balance between innovation and reliability is key. Exploring new materials without compromising performance remains a challenge.

Improving Efficiency: The Role of Smart Hydraulic Valves

Smart hydraulic valves are changing the game in fluid power systems. They offer enhanced efficiency by integrating electronic controls. These valves respond quicker than traditional ones, leading to improved system performance. The ability to adjust in real-time means less energy waste, which is crucial for cost savings.

One tip for optimizing smart valves is to regularly check system settings. This ensures that the components are tuned for maximum efficiency. Over time, settings can drift. Periodic reassessment can help maintain performance.

Data analytics can also play a key role. Monitoring valve performance through sensors can reveal inefficiencies. This information allows for proactive maintenance before critical failures occur. However, relying too heavily on technology can lead to issues. It's vital to balance tech reliance with manual oversight.

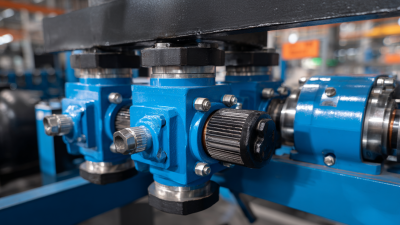

Real-World Applications and Impact of Enhanced Hydraulic Valves

Hydraulic valves play a vital role in various industries. These components control fluid flow, ensuring machinery operates smoothly. Enhanced hydraulic valves can improve efficiency and performance significantly. They allow for faster response times and better pressure control. This offers benefits in construction, manufacturing, and agriculture.

Consider construction equipment. Enhanced valves help cranes lift heavier loads with precision. They respond quicker to operator commands. This reduces wait times during operations. Similarly, in agricultural systems, advanced valves optimize crop irrigation. Farmers can achieve better water distribution. This leads to healthier crops and increased yields.

However, not all innovations are perfect. Some advanced valves may increase installation complexity. Maintenance can become more challenging. Technicians need specialized training to handle them. These potential downsides warrant careful consideration. Balancing innovation with practicality is essential for industry stakeholders.

2026 Best Hydraulic Valve Innovations for Enhanced Performance

Related Posts

-

7 Essential Tips for Choosing the Right Hydraulic Valve for Your Application

-

Understanding the Importance of Hydraulic Pressure Control Valves in Modern Industrial Applications

-

Understanding the Role of Hydraulic Valves in Modern Industrial Applications

-

Exploring the Benefits of Advanced Hydraulic Directional Valves for Efficient Fluid Control

-

2026 Top Hydraulic Directional Valve Trends and Innovations?

-

Understanding the Importance of Hydraulic Flow Control Valves in Modern Industrial Applications