- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

2026 Top Hydraulic Directional Valve Trends and Innovations?

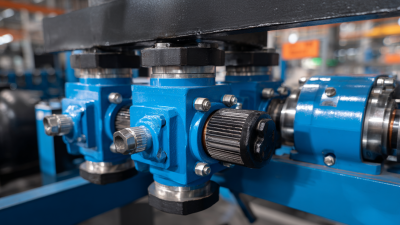

The hydraulic directional valve is a key component in hydraulic systems, controlling the flow and direction of fluid. In 2026, we see exciting trends and innovations emerging in this area. Companies are focusing on enhancing efficiency and reliability while integrating smart technologies.

Recent advancements include improved materials that increase durability and reduce wear. This innovation aims to extend the lifespan of hydraulic directional valves in harsh environments. Additionally, the shift towards automation and IoT connectivity allows for better performance monitoring. It's a game-changer for industries relying on precision and control.

However, challenges persist in achieving optimal performance. Some existing designs struggle with energy consumption and responsiveness. As we delve into these trends, it's essential to reflect on both the achievements and areas needing improvement. Embracing these innovations can pave the way for a more efficient future in hydraulic technology.

Table of Contents

[Hide]

2026 Hydraulic Directional Valve Market Overview and Key Players

The hydraulic directional valve market is evolving rapidly. Understanding the key players helps to grasp current trends. Several companies are competing fiercely, focusing on innovation and improved designs. These players aim to enhance efficiency and reliability in hydraulic systems. They invest in research to develop smarter products.

New entrants to the market introduce diverse technologies. Collaboration among manufacturers fosters advancements. Innovations like advanced materials and electronic controls redefine performance standards. However, some challenges remain. Manufacturers must balance cost and efficiency, which is a delicate dance. Sustainability is also gaining attention, though progress can be slow.

At the same time, customers express varied needs. Some prioritize speed, while others look for durability. This often leads to mismatched expectations between suppliers and buyers. Continuous feedback will be vital as the industry adapts. As new trends emerge, staying informed will be essential for stakeholders.

Emerging Trends in Hydraulic Directional Valve Technology for 2026

The hydraulic directional valve industry is witnessing innovative transformations as we approach 2026. Emerging trends focus on enhancing efficiency and reducing energy consumption. Reports indicate that the global market for hydraulic systems is projected to reach $56 billion by 2026, driven by advancements in technology. This includes the integration of smart controls and IoT for better performance monitoring.

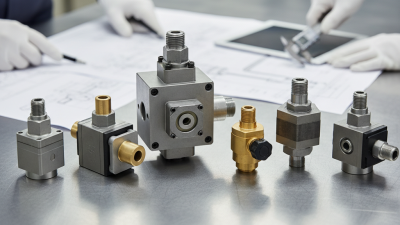

One noticeable trend is the shift toward compact designs. Manufacturers are developing valves that are smaller yet more powerful. This change can lead to space savings in machinery without compromising functionality. Advances in materials science are also contributing. Lightweight yet durable materials enhance reliability, though some may pose challenges during maintenance.

Tip: Always consider the total cost of ownership with new technologies. Sometimes, high efficiency comes with initial complexities.

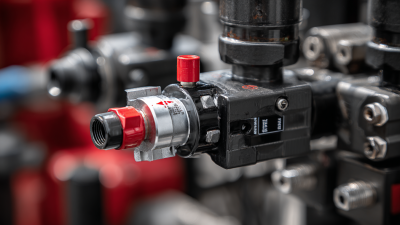

Another interesting trend is automation in hydraulic systems. More companies are adopting remote monitoring and control. While these technologies offer significant advantages, they can also complicate troubleshooting. Over-reliance on automated systems may mask underlying issues.

Tip: Balance automation with manual oversight to ensure system resilience. Emphasize team training for holistic understanding.

Embracing these trends will be essential for industry players, as the landscape continues to evolve.

Innovative Design Features Enhancing Hydraulic Directional Valves

The hydraulic directional valve market is witnessing exciting innovations in design features. Recent studies suggest that the demand for efficient fluid control solutions is increasing. Companies are focusing on reducing energy consumption and enhancing performance. Advanced designs now incorporate integrated circuit technology for improved response times. This technology allows valves to react faster to changing operating conditions, improving overall system efficiency.

In addition, modular designs are gaining traction. These designs enable easy customization and repair. By simplifying maintenance, operators can reduce downtime, a critical factor in industries like manufacturing. Research indicates that modular systems can cut maintenance costs by up to 30%. This is a significant saving for many businesses.

Tips: Look for valves with telemetry systems. These systems provide real-time data on valve performance. This can lead to proactive maintenance, preventing costly breakdowns. Also, consider the environmental impact. Choosing eco-friendly materials can enhance your brand’s reputation. In a competitive market, sustainability matters. It can make a difference to consumers and stakeholders alike.

2026 Top Hydraulic Directional Valve Trends and Innovations

| Trend/Innovation | Description | Impact on Industry | Expected Adoption Rate (%) |

|---|---|---|---|

| Smart Valves | Integration of IoT sensors for real-time monitoring and control. | Increased efficiency and reduced downtime through predictive maintenance. | 40% |

| Lightweight Materials | Utilization of advanced composites and aluminum to reduce weight. | Enhances fuel efficiency in mobile machinery. | 30% |

| Modular Design | Customizable valve architecture that can be easily adapted for various applications. | Reduced lead time for production and improved flexibility. | 35% |

| Energy Efficiency | Design improvements that minimize energy loss. | Lower operational costs and compliance with sustainability regulations. | 50% |

| Enhanced Sealing Technology | Innovative sealing solutions to reduce leakage. | Improved reliability and operational safety. | 45% |

Environmental Impact and Sustainability in Hydraulic Valve Innovations

The drive for environmental sustainability in hydraulic valve innovations is becoming critical. As industries face increasing regulations, companies must adapt. A recent report indicates that the hydraulic component market aims for a 25% reduction in energy consumption by 2026. Implementing eco-friendly materials is one way to meet this goal.

Designing valves with lower emissions is crucial. Research shows that hydraulic systems can account for a significant portion of industrial pollution. For example, innovations in leak-proof sealing technology can dramatically cut oil spillage. Engineers are finding ways to minimize hydraulic fluid use without sacrificing performance. Those who can achieve this will lead the way toward greener operations.

**Tip:** Consider retrofitting older equipment with modern valves that feature sustainable technologies. This can save costs and improve environmental impact.

Sustainability isn't just about compliance; it’s about innovation. Many companies face challenges in balancing cost and environmental responsibility. It's essential to reflect on whether new valve designs truly meet sustainability goals or are simply marketing tools. Regulations will tighten, and adaptation is needed.

Future Prospects and Challenges in Hydraulic Directional Valve Development

The hydraulic directional valve market is rapidly evolving. Innovations focus on efficiency and automation. Recent reports indicate a shift towards smart valves that integrate IoT technology. These valves can enhance system performance by offering real-time data analytics.

However, challenges remain. The integration of advanced technology often drives up costs. Companies may struggle to adopt these innovative solutions due to budget constraints. Additionally, maintaining high reliability while incorporating new features is crucial. If not addressed, this may lead to system failures.

Tips: Consider conducting thorough market research before investing. It’s essential to understand potential return on investment. Training staff on new technologies is equally important for successful implementation. Stay aware of industry trends to remain competitive.

Related Posts

-

Understanding the Importance of Hydraulic Pressure Control Valves in Modern Industrial Applications

-

7 Essential Tips for Choosing the Right Hydraulic Valve for Your Application

-

Exploring the Benefits of Advanced Hydraulic Directional Valves for Efficient Fluid Control

-

Maximizing Efficiency: How Directional Control Valves Transform Hydraulic Systems

-

Understanding the Role of Hydraulic Valves in Modern Industrial Applications

-

Understanding the Importance of Hydraulic Flow Control Valves in Modern Industrial Applications