- Home

- A-Z Catalogue

- Products

- Valves

- Cetop

- Manual Directional Valves

- Proportional Valves

- Poppet Valves

- High-Speed Linear Servo Valves

- All High-Speed Linear Servo Valves

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10

- Cetop 10 (NG32) Two Stage Type High Speed Linear Servo Valves – LSVHG-10 (With Fail-Safe)

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06

- Cetop 8 (NG25) Two Stage Type High Speed Linear Servo Valves – LSVHG-06 (With Fail-Safe)

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04

- Cetop 7 (NG16) Two Stage Type High Speed Linear Servo Valves – LSVHG-04 (With Fail-Safe)

- Cetop 5 (NG10) Direct Type High Speed Linear Servo Valves – LSVG-03

- Cetop 5 (NG10) OBE Type Direct Operated Linear Servo Valves – LSVG-03-EH

- Cetop 3 (NG6) OBE Type Direct Operated Linear Servo Valves – LSVG-01-EH

- Pumps

- Pressure control

- Flow Control Valves

- Pressure Control Valves

- All Pressure Control Valves

- Brake Valves

- Direct Relief Valve

- Low Noise Solenoid Controlled Relief Valves

- Low Noise Pilot Operated Relief Valves

- Pilot Operated Relief Valves

- Pressure reducing and relieving valves

- Pressure reducing and check valves

- Pressure control valves

- Remote Control Relief Valves

- Solenoid Controlled Relief Valves – BSG

- Solenoid Controlled Relief Valves – BST

- Unloading relief valves

- Check valves

- Environmental

- Valves

- Hydraulic Systems

- Power pack

- About Us

- Contact

- Blog

2025 Top Hydraulic Directional Valve Applications and Important Features to Know

In the world of hydraulic systems, the hydraulic directional valve plays a crucial role in controlling the flow and direction of hydraulic fluid, ultimately influencing the performance and efficiency of various applications. As noted by industry expert Dr. Emily Carter, "The hydraulic directional valve is the heart of any hydraulic system, enabling precise control and enhancing overall functionality." This sentiment resonates deeply within many sectors, including manufacturing, construction, and agriculture, where these valves are pivotal for achieving optimal performance.

As we look towards 2025, understanding the important features and applications of hydraulic directional valves is essential for engineers, designers, and technicians. The development of advanced technologies and the increasing demand for automation in hydraulic systems have made it imperative to keep abreast of trends that govern these components. From load-holding capabilities to rapid response times, the innovations surrounding hydraulic directional valves are shaping the future of hydraulic systems. This outline will explore key applications and critical features that professionals need to consider when integrating these vital components into their systems.

Table of Contents

[Hide]

Top Applications of Hydraulic Directional Valves in 2025

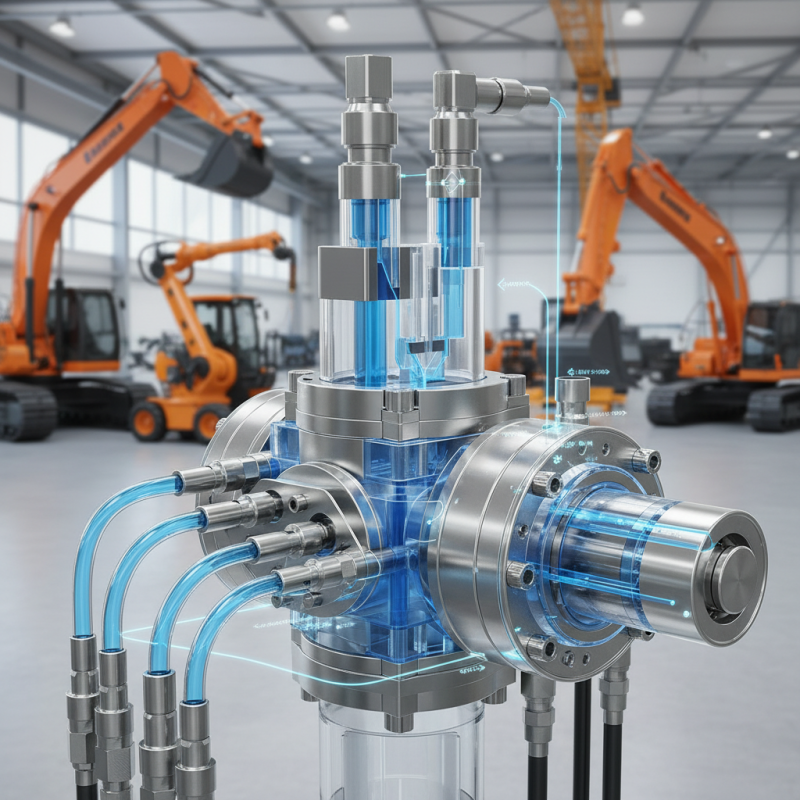

Hydraulic directional valves are crucial components within various industrial applications, serving to control the flow of hydraulic fluids and thus manage the operation of hydraulic systems. In 2025, the top applications of these valves are expected to span across sectors such as construction machinery, agricultural equipment, and automotive technologies. In the construction industry, hydraulic directional valves play a key role in the operation of heavy machinery like excavators and bulldozers, enabling precise control over various hydraulic functions such as lifting and digging.

In addition to construction, agricultural machinery increasingly relies on hydraulic directional valves for efficient operation. These valves enhance the performance of tractors and harvesters by allowing for smoother transitions between different hydraulic functions, which is essential for tasks ranging from plowing to harvesting. Furthermore, in the automotive sector, the utilization of hydraulic systems in vehicle applications emphasizes the importance of directional valves in ensuring safe and reliable operation of features like braking systems and adjustable suspensions. The versatility and adaptability of hydraulic directional valves make them vital across multiple industries, enabling engineers and operators to optimize equipment performance and improve overall efficiency in 2025.

Key Features of Hydraulic Directional Valves to Consider in 2025

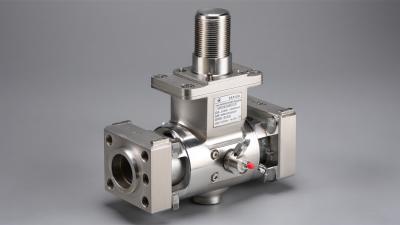

Hydraulic directional valves play a crucial role in the functioning of hydraulic systems, guiding fluid flow to various actuators and components. As we look toward 2025, it is essential to understand the key features of these valves that will be pivotal for achieving efficiency and reliability. One significant aspect to consider is the valve's response time, which impacts overall system performance. According to a report by MarketsandMarkets, the hydraulic valve market is expected to grow by 6.7% annually, highlighting the increasing demand for high-performance valves that can respond rapidly to control signals, thus minimizing downtime and enhancing productivity.

Another critical feature is the valve's sealing performance. As hydraulic systems operate under high pressure, the integrity of seals becomes vital in preventing leaks and ensuring operational safety. Research indicates that advanced seal materials and designs can reduce wear and prolong the lifespan of valves by up to 30%, which not only lowers maintenance costs but also improves environmental sustainability by minimizing fluid loss. Additionally, adaptability is essential; manufacturers are focusing on modular designs that allow for easy customization to meet specific application needs, thereby increasing the versatility of hydraulic systems across various industries from construction to agriculture.

Comparative Analysis of Different Hydraulic Directional Valve Types

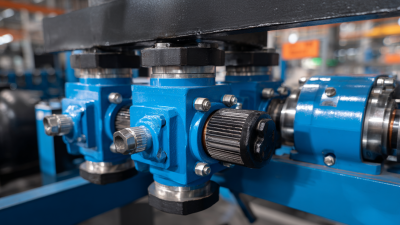

Hydraulic directional valves are essential components in fluid power systems, controlling the flow of hydraulic fluid to different parts of a hydraulic system. The most common types include spool valves, poppet valves, and rotary valves, each with unique characteristics that make them suitable for various applications. Spool valves, known for their versatility and ability to provide multiple flow paths, are widely used in mobile machinery and industrial equipment. Their design allows for precise control of flow direction, making them ideal for applications requiring intricate movements.

On the other hand, poppet valves are favored for their reliability and simplicity. Typically used in low-pressure systems, poppet valves excel in applications where a simple on-off function is necessary. Their robust design minimizes leakage and provides a long service life, which is crucial in maintaining system efficiency. Rotary valves, although less common, are valuable for their ability to handle higher flow rates and pressures. They are often used in applications that demand continuous rotation and can efficiently redirect fluid flow in complex hydraulic circuits.

When selecting a hydraulic directional valve, one must consider factors such as flow capacity, pressure ratings, response time, and installation space. Understanding the specific operational requirements and limitations of each valve type is crucial for optimizing performance and ensuring the longevity of hydraulic systems. An informed choice can significantly affect system responsiveness, efficiency, and overall productivity.

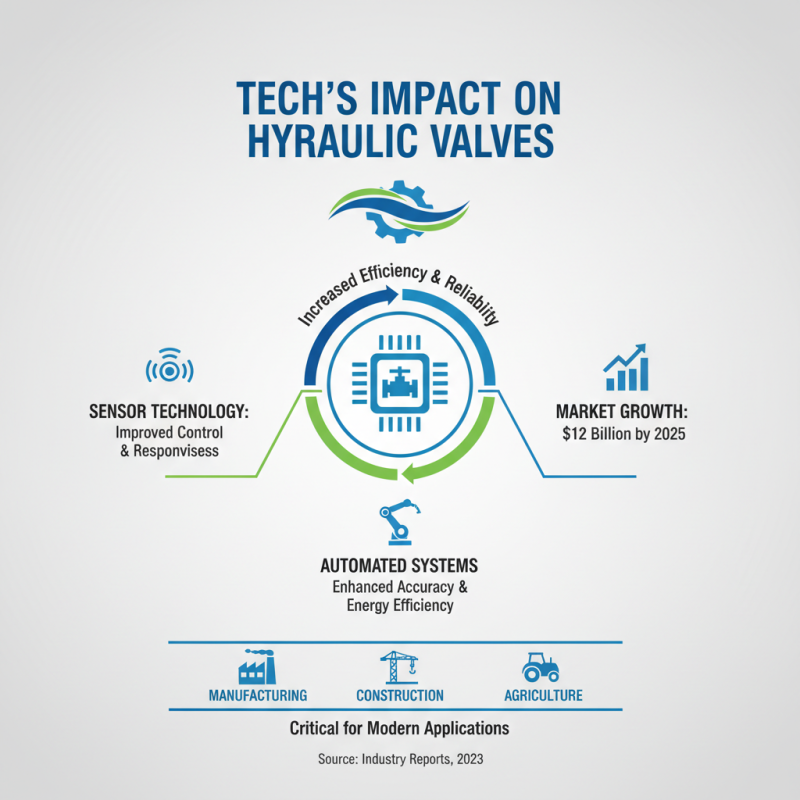

Impact of Technological Advancements on Hydraulic Valve Performance

The impact of technological advancements on hydraulic valve performance has been transformative, particularly as industries strive for increased efficiency and reliability. Recent reports indicate that the hydraulic valve market is projected to grow significantly, reaching approximately $12 billion by 2025, primarily driven by innovations in sensor technology and automated systems. These advancements not only improve the control over hydraulic systems but also enhance responsiveness, accuracy, and energy efficiency, which are critical for modern applications in sectors such as manufacturing, construction, and agriculture.

Furthermore, the integration of IoT (Internet of Things) and smart technology into hydraulic systems has enabled real-time monitoring and predictive maintenance capabilities, reducing downtime and operational costs. According to a study by the International Journal of Advanced Manufacturing Technology, implementing smart hydraulic systems can lead to efficiency improvements of up to 30% in certain applications. The use of advanced materials and design techniques, such as 3D printing, has also contributed to the reduction of the weight and size of hydraulic valves while maintaining high performance standards. This convergence of technologies is creating a new standard for hydraulic systems, promoting not only enhanced performance but also sustainability in industrial operations.

Future Trends in Hydraulic Directional Valve Design and Functionality

The future of hydraulic directional valve design and functionality is poised for significant advancements driven by technology and changing industrial demands. One of the key trends is the integration of smart technologies, which enhances the valves' operational efficiency. By incorporating sensors and advanced controls, these valves can provide real-time data on performance and condition, allowing for predictive maintenance and significantly reducing downtime in hydraulic systems. Moreover, this shift towards smart hydraulic systems facilitates automation and remote operation, aligning with the broader move toward Industry 4.0.

Another important trend is the ongoing development of more compact and lightweight designs without sacrificing performance. As industries focus on energy efficiency and sustainability, hydraulic directional valves are being engineered to reduce material usage while maintaining strength and reliability. This shift not only lowers production costs but also contributes to greener practices by minimizing waste and energy consumption. Additionally, innovations in materials, such as the use of composites and advanced alloys, are enhancing the durability and performance of these valves under various operational conditions, making them increasingly suitable for diverse applications across different sectors.

Related Posts

-

Exploring the Benefits of Advanced Hydraulic Directional Valves for Efficient Fluid Control

-

Exploring the Benefits of Yuken Directional Valves for Enhanced Hydraulic Performance

-

Understanding the Role of Hydraulic Valves in Modern Industrial Applications

-

Understanding the Importance of Hydraulic Pressure Control Valves in Modern Industrial Applications

-

Why Hydraulic Flow Control Valves are Essential for Optimizing System Performance: Insights and Data

-

How to Choose the Right Directional Control Valve for Your Project